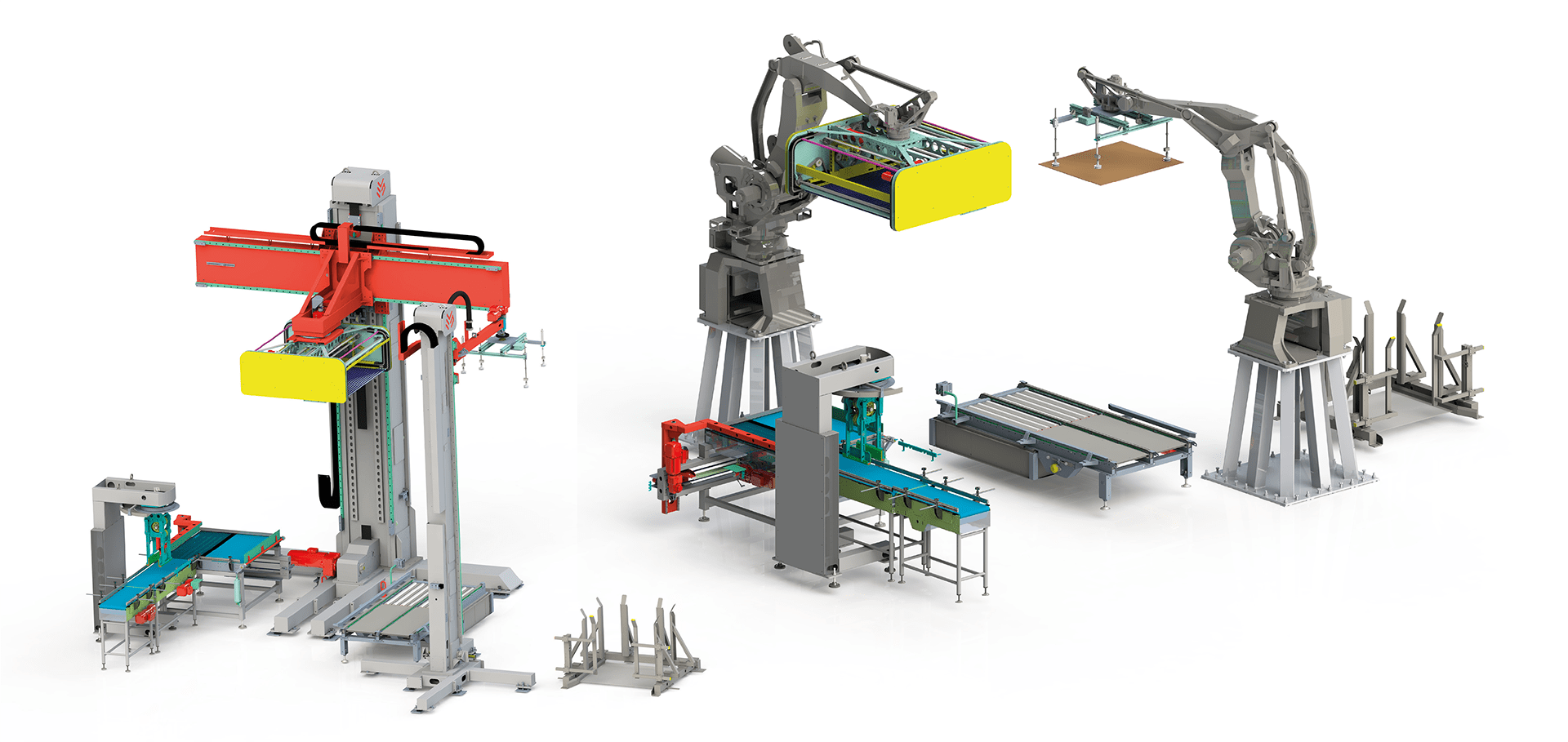

EMS Group palletizing systems: solutions suitable for any sector and need thanks to the modular range design.

The modularity of our palletizing systems enables to handle different types of product with the utmost flexibility and reliability and to meet the needs of several sectors in terms of production speed, increasing line efficiency and reducing maintenance costs.

According to research by the intralogistics monitoring center, artificial intelligence, automation and systems integration are the means employed by companies today to optimize and enhance their intralogistics processes.

The success of the company within the reference sector is determined by the efficient and safe management of the individual flow and the integration of production processes.

The palletizing stage is crucial for the integrity of the product and to ensure stability of the load, in addition to increasing the efficiency of the entire line.

This is why several companies have installed robotic palletizing systems in their production lines, which allow them to quickly, efficiently and safely organize and move products.

Palletizers: what they are and what they are for

A palletizer is an automatic system that arranges products on pallets according to a logic defined as a “palletization scheme”.

The loading units are moved by means of a pick-up device exiting from the primary or secondary packaging stage to the palletizing station.

The palletizing operating modes are set by means of the touch screen control panel, called HMI (Human Machine Interface).

EMS Group: the advantages of a range of modular and flexible palletizers

Our modular palletizers ensure high versatility and reliability for all solutions.

The two palletizing systems – one with a single column structure equipped with a Cartesian system and one with an anthropomorphic robot – can both be implemented with our various interchangeable pick-up heads.

Our various pick-up systems enable management of a wide range of products with complete reliability, ensuring precise pick and place operations and integrity of the product being processed. Depending on requirements, the heads can also be fitted with equipment for handling interlayers, pallets and frames.

Thanks to the utmost flexibility in application and layout configuration, our palletizers can be integrated both in new plants and in projects to revamp existing lines.

The compact and flexible layouts also ensure high accessibility for restoring (cleaning) and maintenance activities.