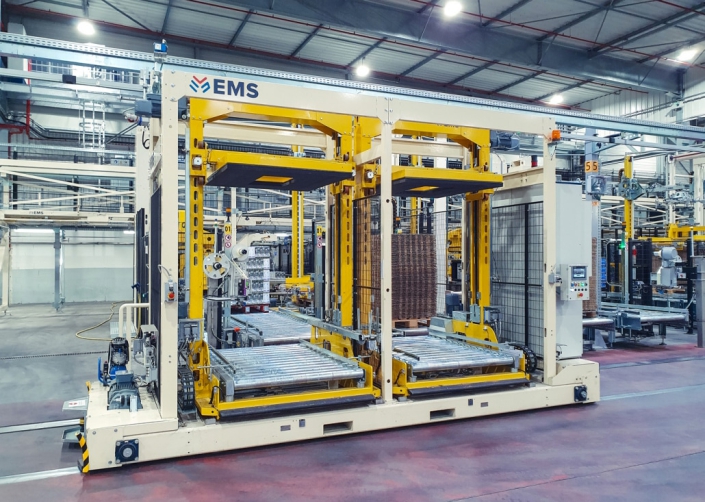

EMS Group conveying lines: a complete engineering service for integrated and customized solutions

The automation of goods and materials handling is essential to ensure production and intralogistic processes optimization and to protect the integrity of products, as it guarantees synchronized and safe goods transportation from one processing station to another.

EMS Group designs and produces robotic unwrappers and destrappers, depalletizers, empty pallets preparation systems, american carton packaging lines, craters/decraters, basket loaders/unloaders, palletizers, robotic labelers, systems for intralogistics and automated storage management. In addition, the Group provides a complete engineering service for the construction of conveying lines.

Our conveying lines use different conveying systems to guarantee the optimal solution based on the type of product processed, plant layout and capacity.

We design and produce conveying lines for:

- Empty, full and packaged PET

- Aluminum and tinplate cans

- Empty, full and packaged glass containers

- HDPE containers, bins, crates, cartons, trays, bundles and jerry cans, pouches, etc.

Our solutions meet the needs of various industries because they are complete with optionals for both empty/full containers and loading unit handling, such as:

- Single-lane, multi-lane, FIFO and FILO accumulation tables

- Continuous and non-continuous dividers

- Aligners

- Merry-go-round accumulation tables

- Transfers, orienters and spacers

- Elevators, lowerators, overturners and “Omega” machines

- Camera orienters for asimmetrical containers

Some of our optionals’ strengths:

- Sturdiness.

- Flexible configurations.

- Modular and optimized design in order to simplify future upgrades.

- Reduction in installation costs and timing.

Our range also includes full pallets elevators and lowerators, which efficiently and safely transport loading units and recover differences in height inside the factory.

Again, the flexibility of our solutions allows for different products handling, and layout configurations are always tailored according to the characteristics of customer’s plant.

The transportation of packing materials and loading units can be automated through shuttles on rail or AGVs.