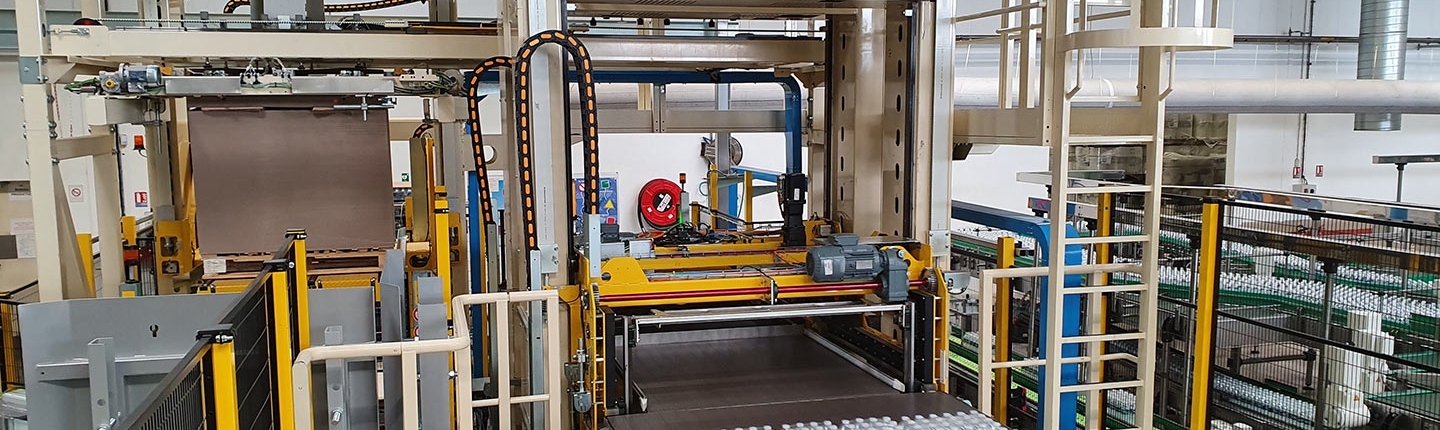

12 layers per minute: here is the MT576 RedFox 3 palletizer

Interview with Paolo Biondi, Food & Beverage Sales Director – EMS Group

What type of machine is MT576 RedFox 3?

MT576 RedFox 3 is a palletizer. The performances of the previous version, RedFox 2, with two manipulators were so impressive that we decided to further evolve the machine fitting brushless motors to power specific movements and making some additional arrangements for layer pad transfer.

After these changes, the machine potential was huge, so we had to enhance performances in the layer preparation area, which was originally a point of strength of our system, but which had become a bottleneck.

The need to make up for the new output requirements of the lifting system with two carriages has required the installation of a third manipulator featuring RedFox technology.

Our estimated output is 80,000bp/h for the 1.5L format and 120,000bp/h for the 0.5L format, although I am fully convinced that we have the potential to exceed these outputs: 12 layers per minute is the result we have achieved in production with the machine running at lower speeds than in real conditions. At higher speeds we are very likely to hit 150,000 bottles per hour with the half litre format!

Thanks to this potential, MT576 RedFox 3 deserves the attention of the leading mineral water producers in the world as this machine alone can guarantee extremely high outputs.

Another advantage of this new multi-functional palletizer, which must not be underestimated, is the possibility to configure it in two versions: with the infeed from the bottom and with the infeed from the top. This enables feeding of the packs/cartons/boxes to be palletized from two levels, which is why our system can meet the requirements of bottling lines having these types of infeed configuration.

What does a palletizer do?

Palletizers are machines designed for palletization. In other words, they form a layer of product to be loaded on a pallet according to a programmed pattern. The layer must be such as to fit the pallet format in use (European, American, British pallets or half pallets, quarter pallets, etc.). The machine must be designed so as to form a “mosaic” of products that are palletized for either stocking or shipping purposes. The final pallet must be as uniform as possible, with product covering its entire surface, without any protruding parts. The palletizer can also be configured to create empty vertical spaces inside the pallet (“stacks”) so that the outer walls are easy to shrink-wrap or cover with a stretch hood and the pallet is stable, protected and easy to ship to its final destination.

The palletizer is finally intended to automatically form a palletized load.

Why and/or to what extent is the Redfox technology different?

RedFox is our layer preparation unit and it has been raising the interest of many since it was firstly created.

It is not brand new technology in absolute terms as other companies have been using this type of manipulators. However, one of the advantages of the RedFox solution is stability: we are one of few to offer a fully welded rigid frame. Over the years, the frame has been further reinforced to withstand the increasingly rapid movements required from pack manipulators.

This is a distinguishing feature from other manufacturers who use modular systems in which horizontal transfers at high speeds are not implemented smoothly.

Another advantage of the RedFox system is complete control over the gripper: the use of brushless motors for both horizontal / transverse / vertical movements and for gripper closing around the product enables monitoring the pressure exerted on the pack in order to identify whether the pack protrudes from the pallet, whether excessive pressure is being exerted which may damage the product, and whether the products fed into the palletizer have been damaged by the machines upstream.

Let me also add, for the sake of exemplification, that some competitors use manipulators powered by either fully pneumatic or partially pneumatic systems (i.e. pneumatic only on one side as the other is fixed): this does not provide for punctual control of the exerted pressure as the RedFox system does.

The great benefit of identifying damaged products at the palletizer infeed may be negligible when it comes to plastic containers, but it is quite crucial with sensitive containers such as glass bottles. Glass fragments are prevented from entering the palletization area, thus avoiding damage to the system and long machine downtimes for cleaning operations.

The possibility to accurately monitor the size of the infeeding pack also allows for multiple pack manipulations, meaning that 1 up to 6 packs can be grouped simultaneously as the RedFox system can change the size of the gripper based on the products currently processed or to be processed.

What is the benefit of having 3 manipulators?

The need to study a solution with 3 manipulators is mainly connected with speed.

The machine software has a function to identify the number of manipulators required to meet the production requirements. The amount of products a manipulator can process in a unit of time is affected by a set of parameters: the software calculates the different combinations and optimises production.

What is the benefit of stacking 12 layers per minute?

The need to stack 12 layers per minute did not actually come from customers; it was rather a challenge we intended to address. The machine we had to offer our customers to meet their production requirements was close to its limit capabilities.

Although the similarities are many as regards the frame, the previous model (MT576 RedFox 2)is not supplied with some brushless motors and the function to handle layer pads at a height, and it runs at a max. speed of 8 layers per minute (if you take as reference a palletization pattern of unstable products stacked in 4 layers, the production capacity increases sensitively if the number of layers is increased and stable products are palletized).

With these new arrangements and thanks to extremely robust mechanics – a constant feature of EMMETI machinery -, we have carried out some tests in-house and we have noted that 12 layers per minute were a viable target, both in terms of transfer speed and lifting and translation speed. It was just a matter of synchronising the movements at best and taking advantage of the return speeds without load which we could not reach with asynchronous motors.

The advantage of stacking 12 layers per minute is huge: up to a few years ago these speeds were only conceivable with 2 machines. As of today, the possibility to achieve them with one machine only and with pallet feeding from below (more comfortable loading of consumables, easier pallet transfer to automated internal logistic systems) opens up completely new scenarios for bottling systems.

MT576 RedFox 3 is a very high speed machine which does not require to be manned, it provides for enhanced visibility over all its parts, it is easier to load and designed to manage pallet/layer pad changeover in automatic mode without any machine shutdown as these operations are performed outside the palletization area.

Our initial customer’s requirement was the worst-case scenario ever: to handle 60,000 bph (1.5L format), released from the filler in 3×2 packs sitting on half pallets. When the min. overspeed was applied to the filler for correct system sizing, we realised that 12 layers per minute were not a far away target from what we wanted to achieve, after all.

What is the future of RedFox 3?

A bright future! Considering the performances we have managed to hit in the configuration we have experimented, RedFox 3 can smoothly withstand the speed of 12 layers per minute, thus eliminating the bottleneck at the stage of layer formation. On a potential basis, this will help us focus again on the development of palletizer MT576 with a view to climbing high up to new performance peaks and to meeting ever more stringent requirements.

We are also continuing to study and implement even more evolved RedFox technology, in which brushless motors are replaced with new experimental solutions, that may be used in applications starting from next year.

This may mark a revolution for this machine component which we, as EMMETI first and EMS Group now, have managed to bring to unparalleled performance peaks that are hard to equal.

We will carry on introducing new technology to further raise the bar and stand out against our competitors.

Can this technology be applied to other products / industries?

The beverage industry pioneered the introduction of this solution. Very high speeds are normally at stake in bottling lines which are thus an ideal bench to test strength against stresses and the machine life cycle over time.

RedFox is also extensively used in the food and chemical/pharmaceutical industries where the machines run at very high speeds, on the one hand, and product manipulation is required to be precise, safe and in compliance with the “facing” requirement, i.e. packs must be placed on the pallet with visible parts (product data, bar code, etc.) facing outwards. This feature is included free of charge in RedFox technology: the wide configuration capability of the software enables the product to be turned either clockwise or anticlockwise, and without the need to fit ancillary parts.