Palletizing systems: advantages and solutions

The palletizing stage is crucial for the integrity of the final product and to ensure load stability during handling, as well as to increase the efficiency of the entire line.

For these reasons, the use of automated palletizing systems is increasingly important for companies that want to optimize their production processes.

An automatic palletizer is a system that handles product units exiting the primary or secondary packaging stage and deposits them on pallets in an orderly and safe manner, according to a predetermined logic that is called a “palletization scheme”.

The palletizing operating modes and the format changeovers are set by means of the touch screen control panel, called HMI (Human Machine Interface).

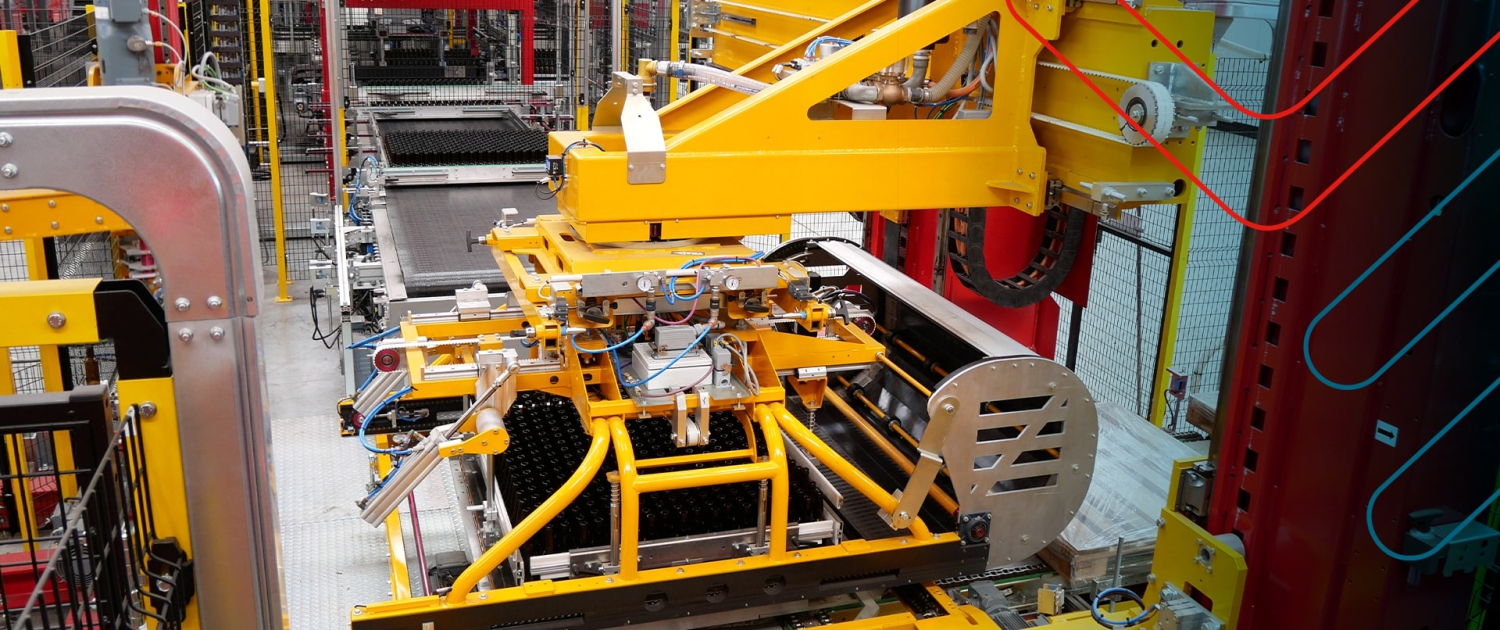

At EMS Group, we provide palletizing solutions suitable for every industry thanks to a modular and flexible range of palletizers: the two main models – one with a structure equipped with a Cartesian or polar handling system and one with an anthropomorphic robot – can both be complemented with our many interchangeable pick-up heads.

The various grippers make it possible to manage a wide range of products with full reliability, always guaranteeing precision in pick and place operations and the integrity of the product being processed.

If necessary, the heads can also be provided with equipment for handling layer pads, pallets and frames.

Completing the range for the Food & Beverage industry is the double-lifter palletizing system, which offers high production capacity with low level infeed.

All solutions guarantee maximum configuration flexibility, enabling us to integrate our systems into both new systems and existing lines.

The quality of the systems used to prepare the layer is also important to ensure product integrity and operational efficiency even upstream of the actual palletizing stage.

Once more, EMS Group offers solutions to meet the needs of many industries:

- Sweep-off or pick-and-place stackers to manage products which preclude accumulation (e.g., bottles or empty glass jars).

- Robotic manipulators that enable multiple simultaneous gripping, up to 8 units of product.

- REDFOX, our modular layer preparation system.

REDFOX guarantees total application flexibility and high operational autonomy thanks to the three independent manipulator units with variable opening grippers and to the software that analyzes the workload on the manipulators according to the type of product and line speed to ensure the highest quality in layer preparation and production optimization.

The robust manipulator structure makes for quick and safe handling of product units, while the system also features a setting for orienting packages to ensure identification and traceability.

The implementation of reliable and high-performance automated palletizing solutions is therefore essential for companies that want to increase their competitiveness, both in terms of business optimization and of the quality and safety of the product offered to the market.

With engineering expertise gained in various fields and its focus on the customer, EMS Group is the ideal partner to rely on.