Our palletizing systems are designed according to a modular concept that involves two types of palletizers to implement with interchangeable pick-up heads: one palletizer with a single column structure equipped with a Cartesian system and one with an anthropomorphic robot.

The range also includes specific applications by sector.

All our palletizers ensure:

- Maximum application and layout configuration flexibility.

- High efficiency.

- Accessibility for cleaning activities and maintenance.

The various pick-up heads enable management of a wide range of products with full reliability, ensuring pick and place operation precision and integrity of the product being processed. Depending on requirements, the heads can also be equipped with equipment for handling interlayers, pallets and frames.

PALLETIZING SYSTEMS

SCEGLI I SISTEMI DI PALLETTIAZZIONE IN BASE AL TUO SETTORE

PALLETIZING SYSTEMS

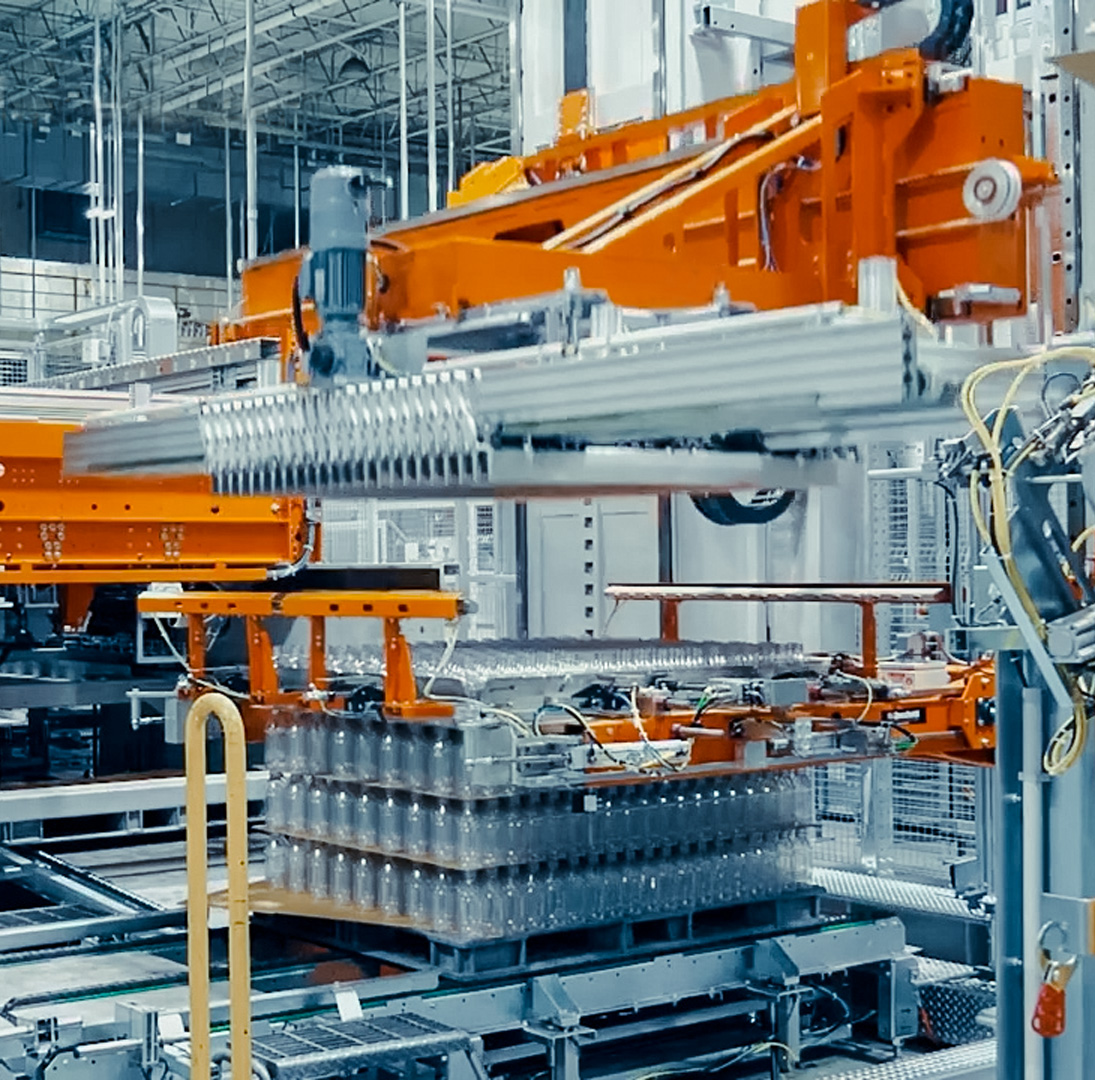

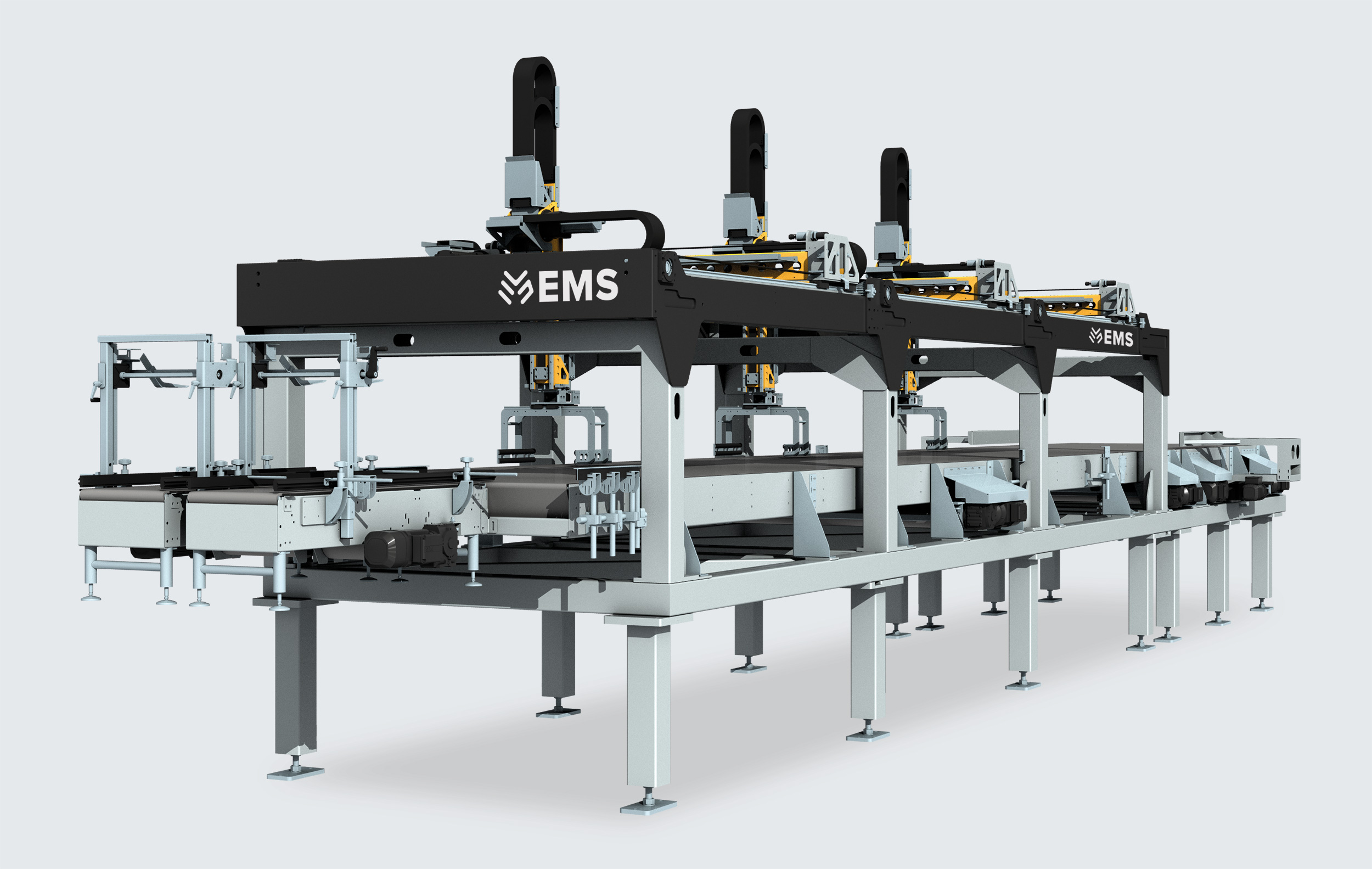

R-PAL / T-PAL

SINGLE-COLUMN ROTATING OR TRANSLATING FOR ENTIRE LAYER

Up to 5.5 layers/minute

STRENGTHS

- Maximum layout configuration flexibility.

- Simple installation.

- Format change directly from HMI.

- Reduced maintenance thanks to the use of toothed belts.

- Anti-fall system for all the hanged loads.

- High accessibility.

R-PAL / T-PAL

SINGLE-COLUMN ROTATING OR TRANSLATING

Up to 7 cycles/minute

STRENGTHS

- Maximum layout configuration flexibility.

- Simple installation.

- Format change directly from HMI.

- Reduced maintenance thanks to the use of toothed belts.

- Anti-fall system for all the hanged loads.

- High accessibility.

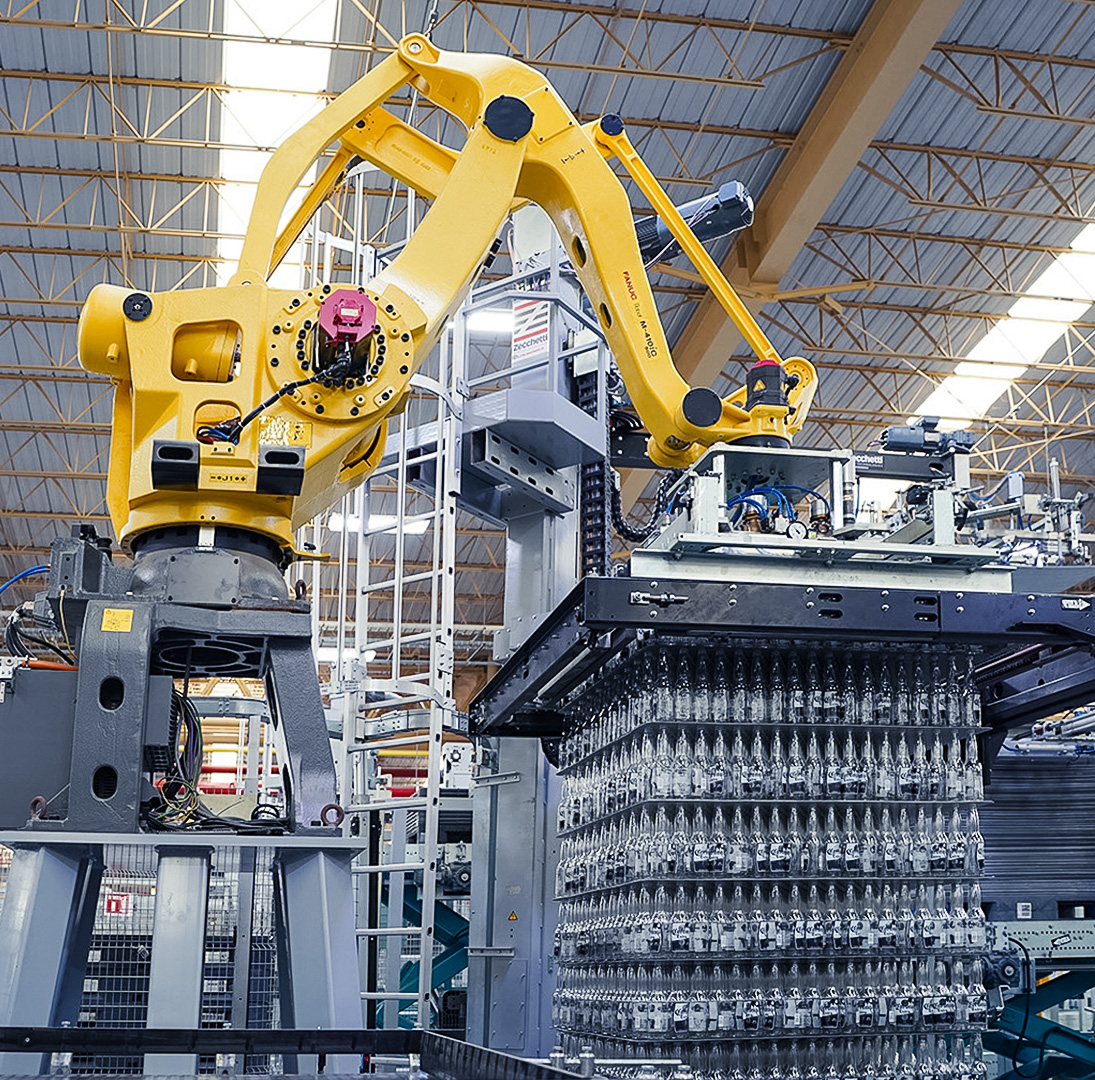

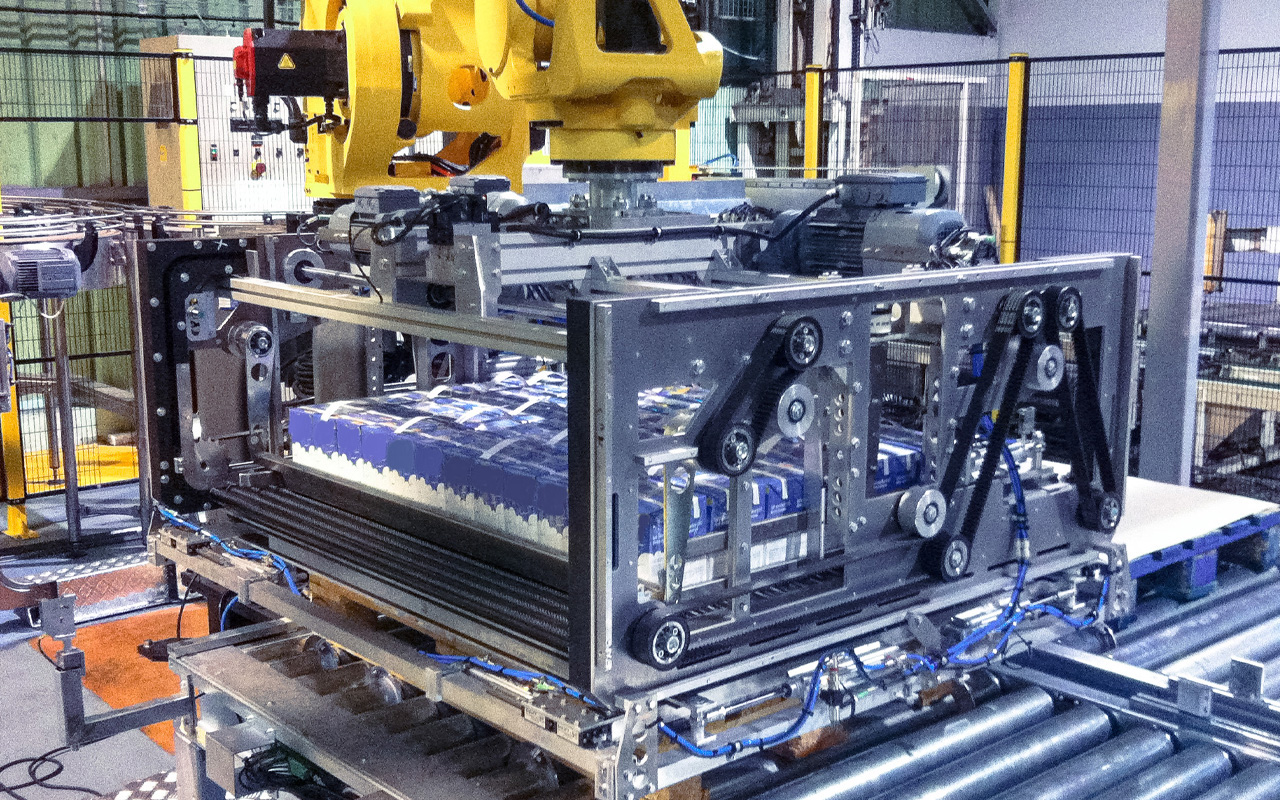

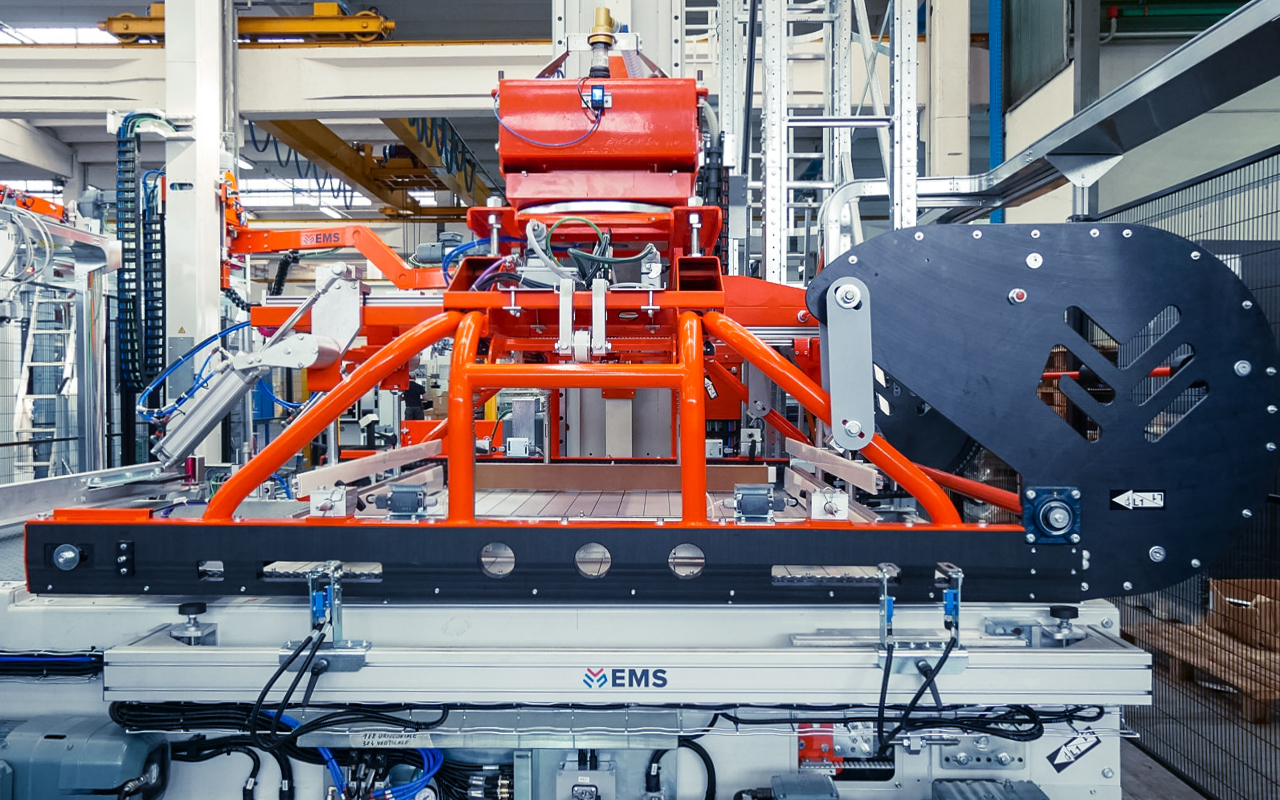

ROBO-PAL

ANTHROPOMORPHIC ROBOT FOR ENTIRE LAYER

Up to 7 layers/minute

STRENGTHS

- MTBF: 60,000 hours.

- High production capacity.

- Possibility to work simultaneously on several stations.

- Maximum configuration flexibility.

- Format change directly from HMI.

- Simple installation.

- Low maintenance costs.

- High accessibility.

ROBO-PAL

ANTHROPOMORPHIC ROBOT

Up to 11 cycles/minute

STRENGTHS

- MTBF: 60,000 hours.

- High production capacity.

- Possibility to work simultaneously on several stations.

- Maximum layout configuration flexibility.

- Format change directly from HMI.

- Simple installation.

- Low maintenance costs.

- High accessibility.

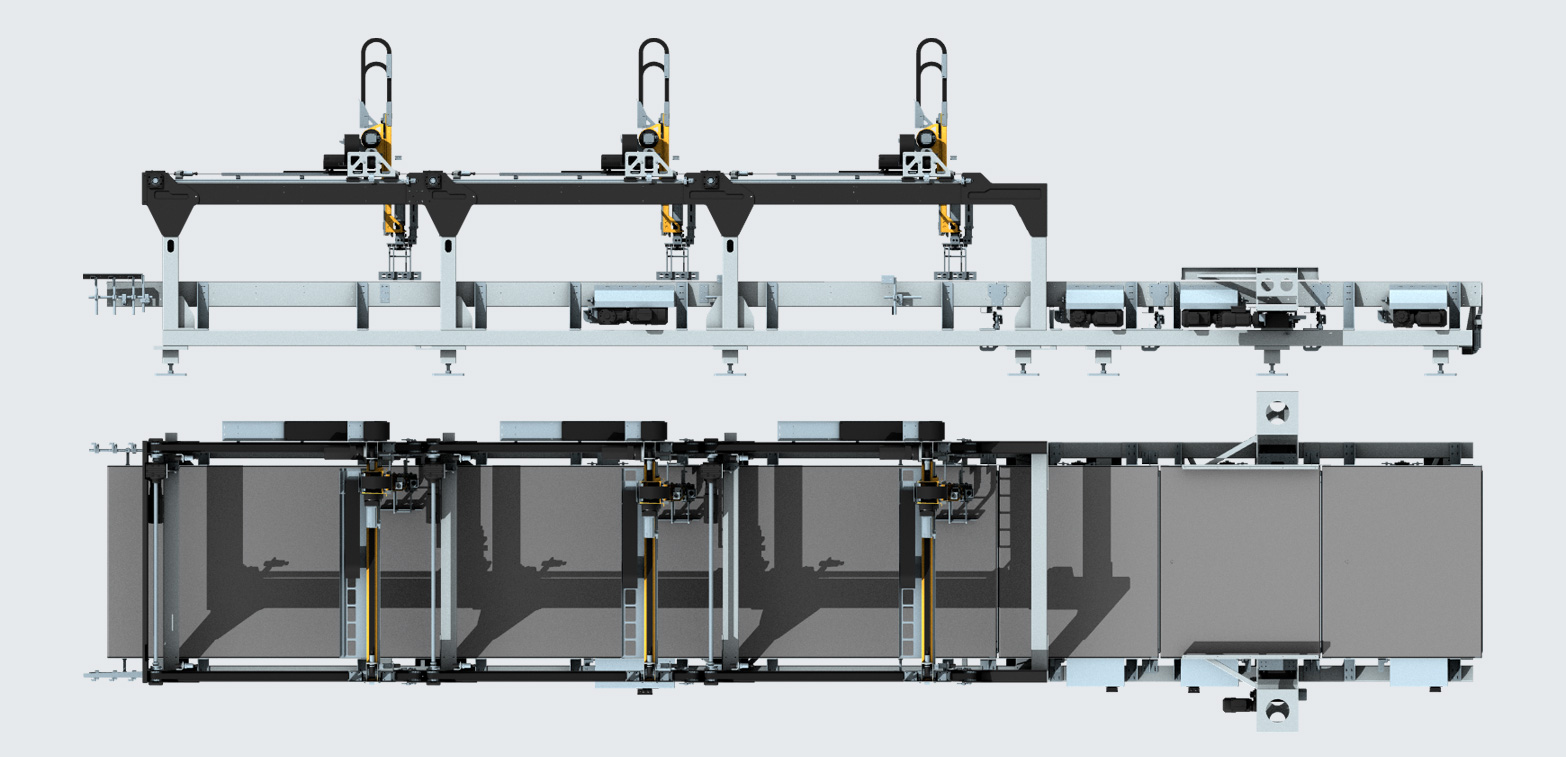

TWIN-PAL

HIGH SPEED DOUBLE LIFTER

7 to 11 layers/minute

STRENGTHS

- High production capacity with low level product infeed.

- Format change directly from HMI.

- Reduced maintenance thanks to the use of toothed belts.

- Anti-fall system for all the hanged loads.

TWIN-PAL

HIGH SPEED DOUBLE LIFTER

7 to 11 layers/minute

STRENGTHS

- High production capacity with low level product infeed.

- Format change directly from HMI.

- Reduced maintenance thanks to the use of toothed belts.

- Anti-fall system for all the hanged loads.

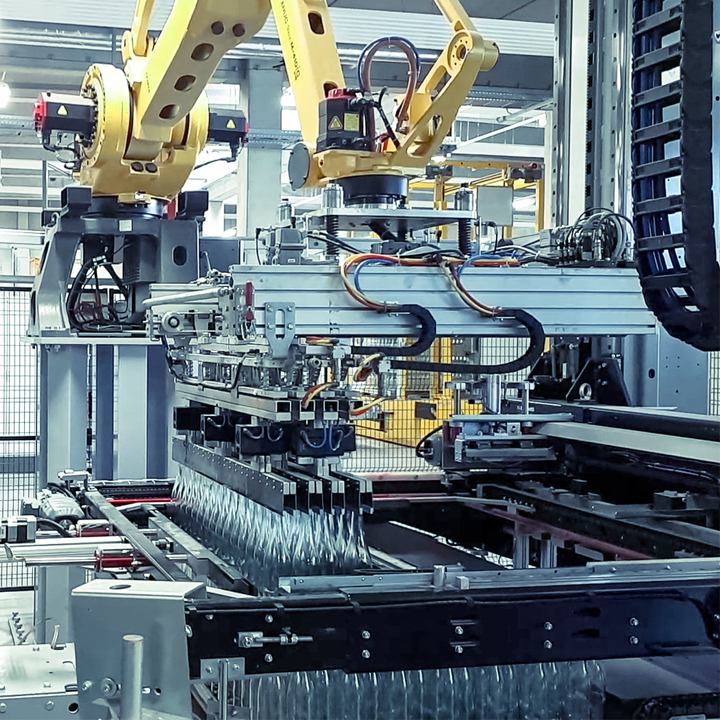

ROBO-PAL

HIGH SPEED ROBOTIC

7 to 10 layers/minute

STRENGTHS

- MTBF: 60,000 hours.

- High production capacity.

- Maximum flexibility and reliability in product handling.

- Versatile layout configuration.

- Reduced footprint.

- Format change directly from HMI.

- Low maintenance thanks to the few moving mechanical components.

ROBO-PAL

HIGH SPEED ROBOTIC

7 to 10 layers/minute

STRENGTHS

- MTBF: 60,000 hours.

- High production capacity.

- Maximum flexibility and reliability in product handling.

- Versatile layout configuration.

- Reduced footprint.

- Format change directly from HMI.

- Low maintenance thanks to the few moving mechanical components.

R-PAL

ROTATING SINGLE-COLUMN

Up to 4 layers/minute

STRENGTHS

- Adequately oversized components for “around-the-clock” operation.

- Innovative sweep-off or pick-up stackers for feeding and preparing rows of items.

- Possibility of implementing the patented universal palletizing head MPH (Multi-Purpose Head).

- Progressive and extremely accurate movements.

- Absolutely gentle product handling and maximum precision in setting up full pallets.

- Great operational flexibility thanks to the possibility of varying the speed according to the production lines.

- Reduced wear of the installed components thanks to the absence of vibrations or stress.

- Compact layout.

- Format change directly from HMI.

- Reduced maintenance thanks to the use of toothed belts.

- Anti-fall system for all the hanged loads.

- Full accessibility.

T-PAL

TRANSLATING SINGLE-COLUMN

Up to 4 layers/minute

T-PAL is ideal for contexts that require a small footprint and high configuration flexibility.

STRENGTHS

- Robust, compact and fully accessible.

- Adequately oversized components for “around-the-clock” operation.

- Innovative sweep-off or pick-up stackers for feeding and preparing rows of items.

- Possibility of implementing the patented universal palletizing head MPH (Multi-Purpose Head).

- Progressive and extremely accurate movements.

- Absolutely gentle product handling and maximum precision in setting up full pallets.

- Great operational flexibility thanks to the possibility of varying the speed according to the production lines.

- Format change directly from HMI.

- Reduced wear of the installed components thanks to the absence of vibrations or stress.

- Reduced maintenance thanks to the use of toothed belts.

- Anti-fall system for all the hanged loads.

- Full accessibility.

ROBO-PAL RBR

ANTHROPOMORPHIC ROBOTIC FOR PACKS/ROWS

Up to 8 cycles/minute

It is an innovative solution that is primarily designed to process shaped and unstable items.

STRENGTHS

- MTBF: 60,000 hours.

- Maximum reliability in product handling as there is no stacker and layer preparation table: the bottles are picked up by the head directly from the conveyors and deposited on the pallet, in the correct position, via pick-and-place operations.

- Format change directly from HMI.

- Flexible and very compact layout configurations.

ROBO-PAL RBR

ANTHROPOMORPHIC ROBOTIC FOR PACKS/ROWS

Up to 11 cycles/minute

PUNTI DI FORZA

- MTBF: 60,000 hours.

- Flexible and very compact layout configurations.

- Possibility of also managing the support materials with the pick-up head.

- Format change directly from HMI.

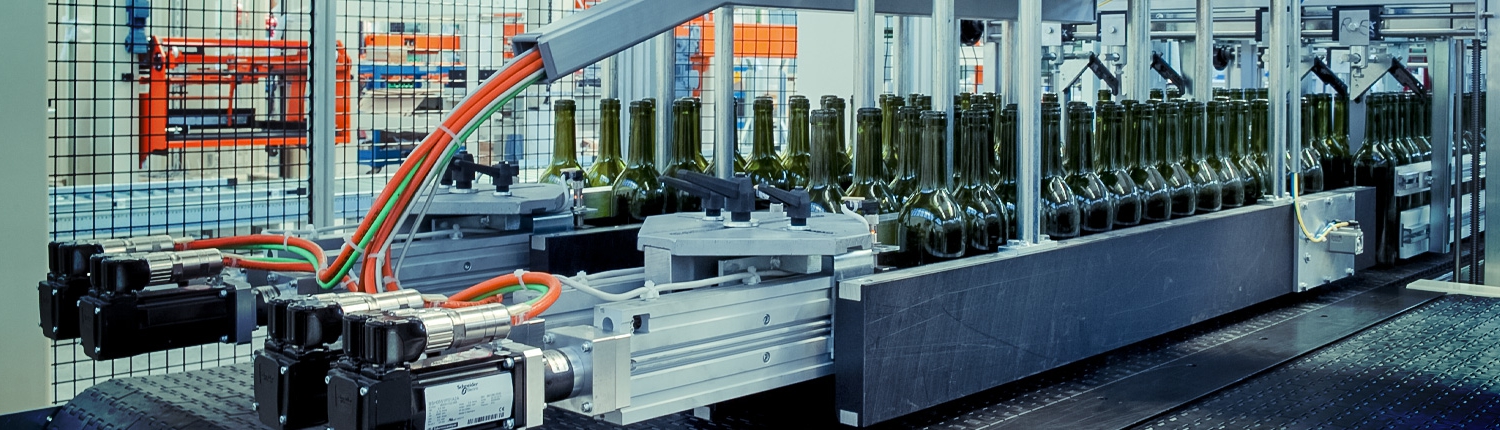

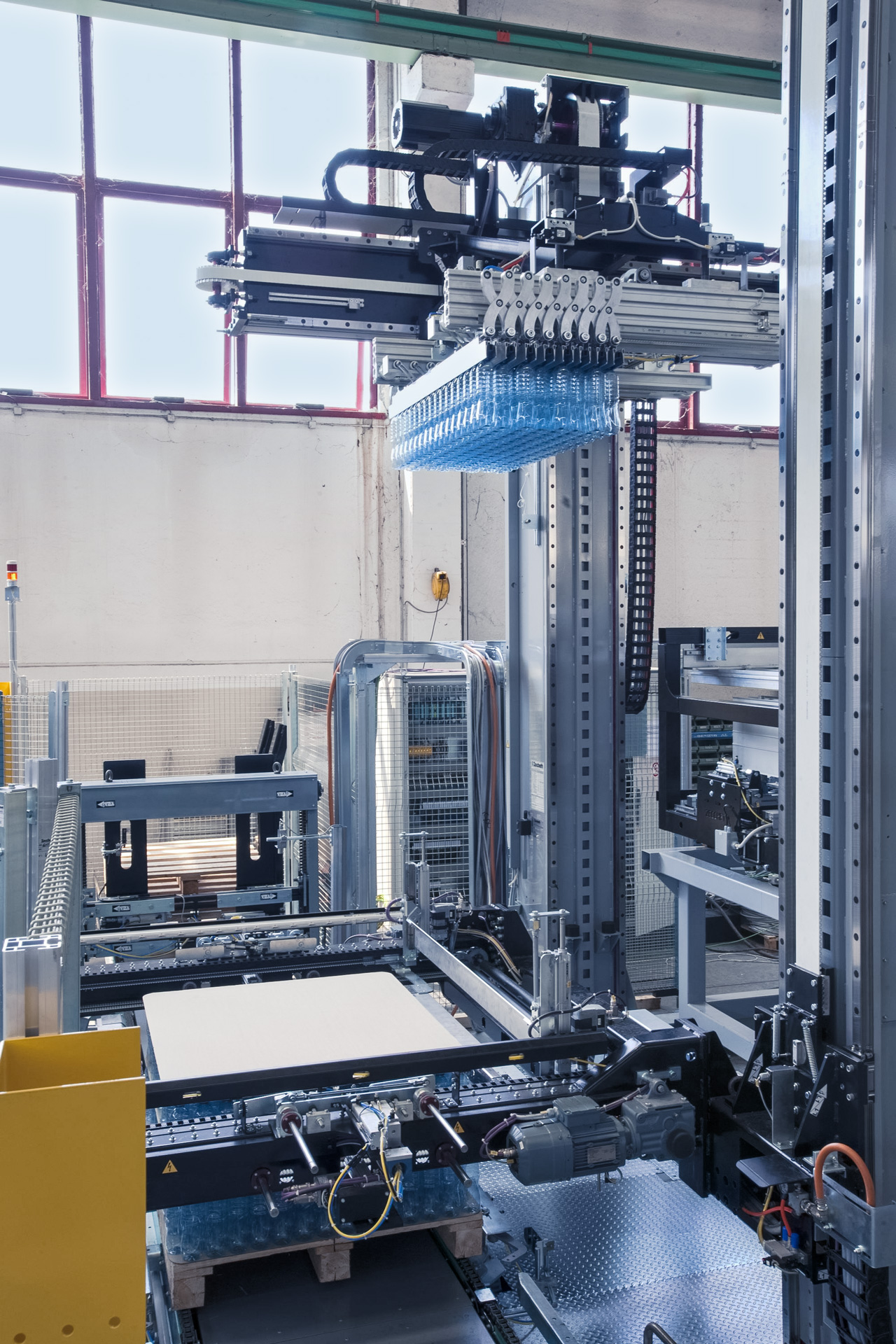

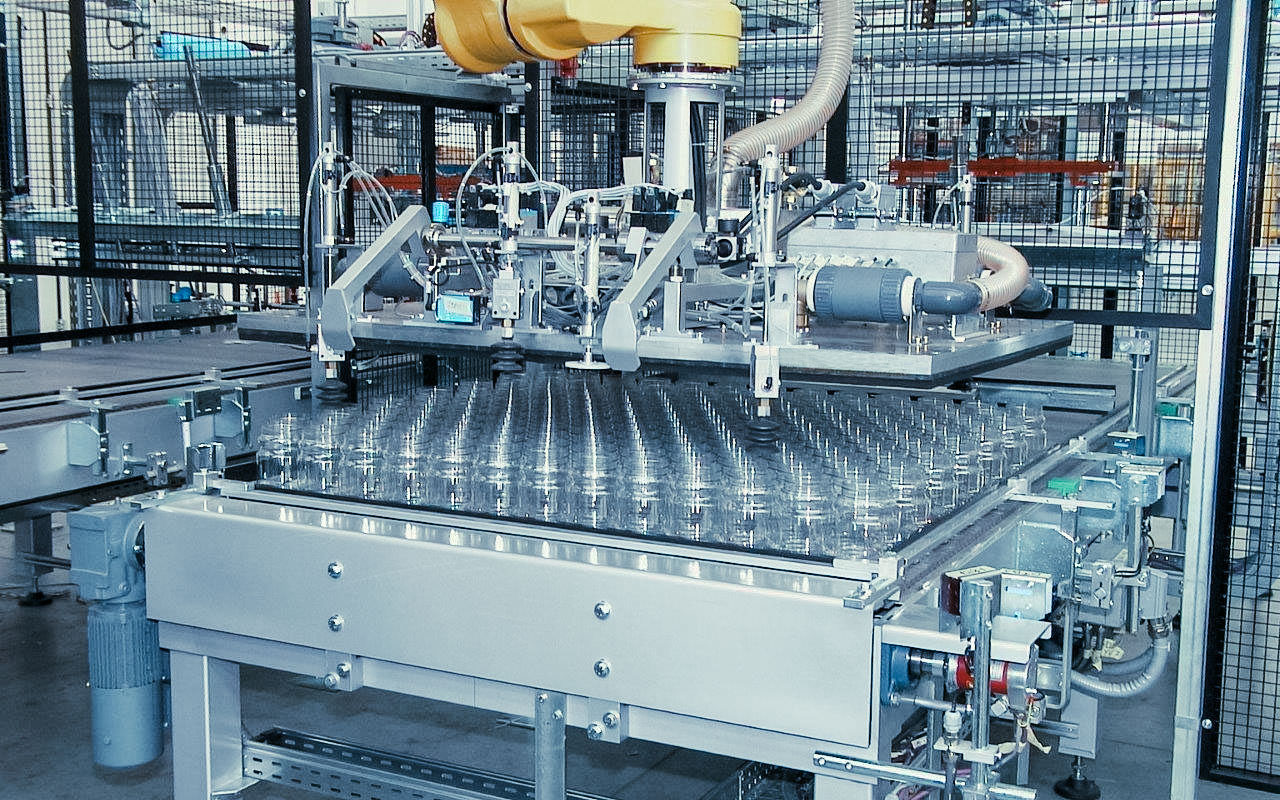

EASY-PAL

TRANSLATING SINGLE-COLUMN

Up to 4.5 layers/minute

EASY-PAL is the ideal solution for high-speed palletizing of empty bottles managed by air conveyors.

STRENGTHS

- High production speed with a small footprint.

- Maximum reliability in product handling as there is no stacker and layer preparation table: the bottles are picked up by the head directly from the conveyor lanes and deposited on the pallet.

- High efficiency in managing the incoming bottle flow.

- High-precision row formation thanks to the bottle feeding and counting system with transmission belts and fiber-optic photocells.

- Format change directly from HMI.

- High accessibility.

- Reduced maintenance thanks to the use of toothed belts.

- Anti-fall system for all the hanged loads.

RBR-PAL

SINGLE-COLUMN FOR PACKS/ROWS

Up to 7 cycles/minute

It is the ideal solution with a row pick-up head for palletizing HDPE bottles and special PET containers in lines that require several format changes.

STRENGTHS

- Maximum reliability in product handling as there is no stacker and layer preparation table: the bottles are picked up by the head directly from the conveyor lanes and deposited on the pallet in the correct position.

- Safe layer centering thanks to the system that retains the rows of bottles already deposited both during layer formation and squaring, as well as the perimeter guides for layer compaction and centering.

- Format change directly from HMI.

- Can be integrated with air or chain conveyors.

- Reduced maintenance thanks to the use of toothed belts.

- Anti-fall system for all the hanged loads.

- High accessibility.

TESTE

VISUALIZZA LE TESTE IN BASE AL TIPO DI PALLETTIZZATORE

HEADS

BASKET

Complete layer pick-up head with motorized central opening system.

CURTAIN

Universal palletizing and depalletizing head complete with motorized layer compacting guides.

MAGNETIC

Magnetic head with automatic quick release grid.

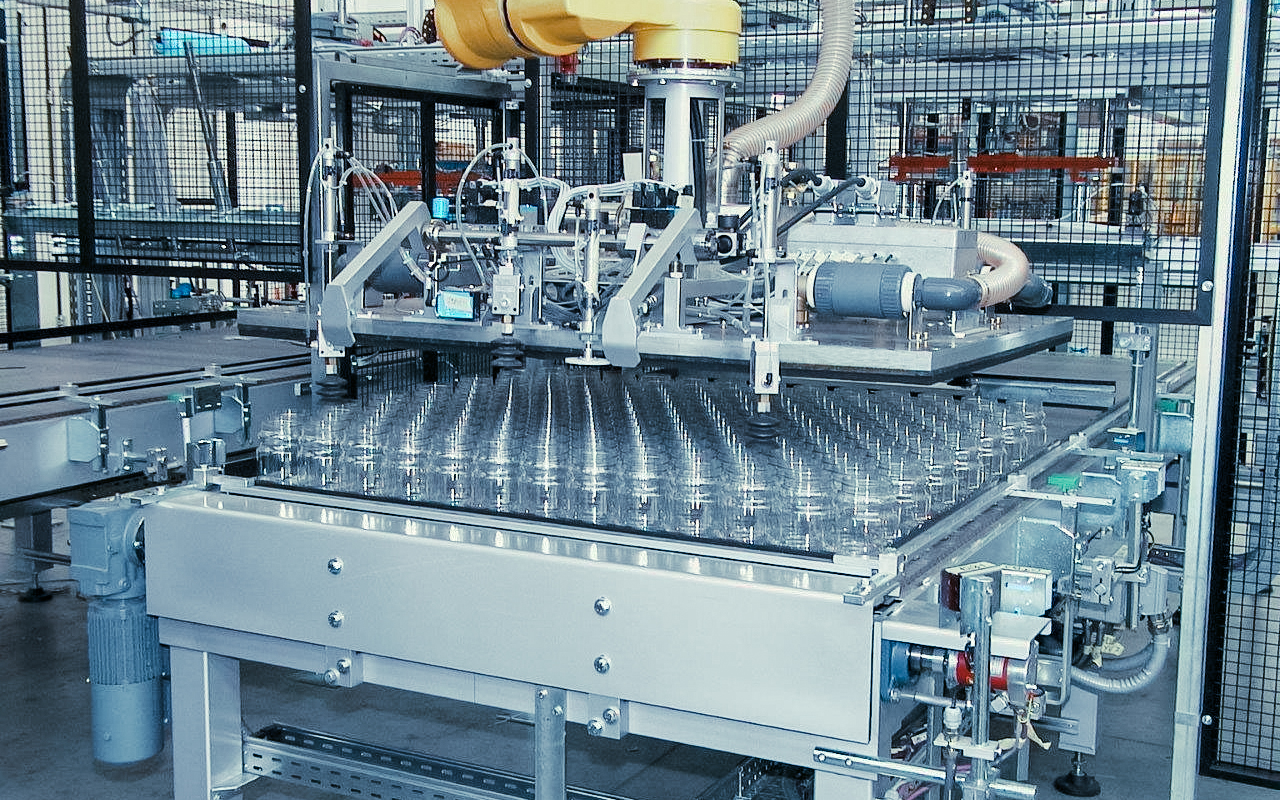

VACUUM

Vacuum pick-up head ideal for handling glass jars, loose, bundled and clustered cans and boxes.

UNIVERSAL SIDE PICK-UP AND VACUUM

Universal vacuum pick-up head complete with lateral electro-pneumatic controlled compaction guides.

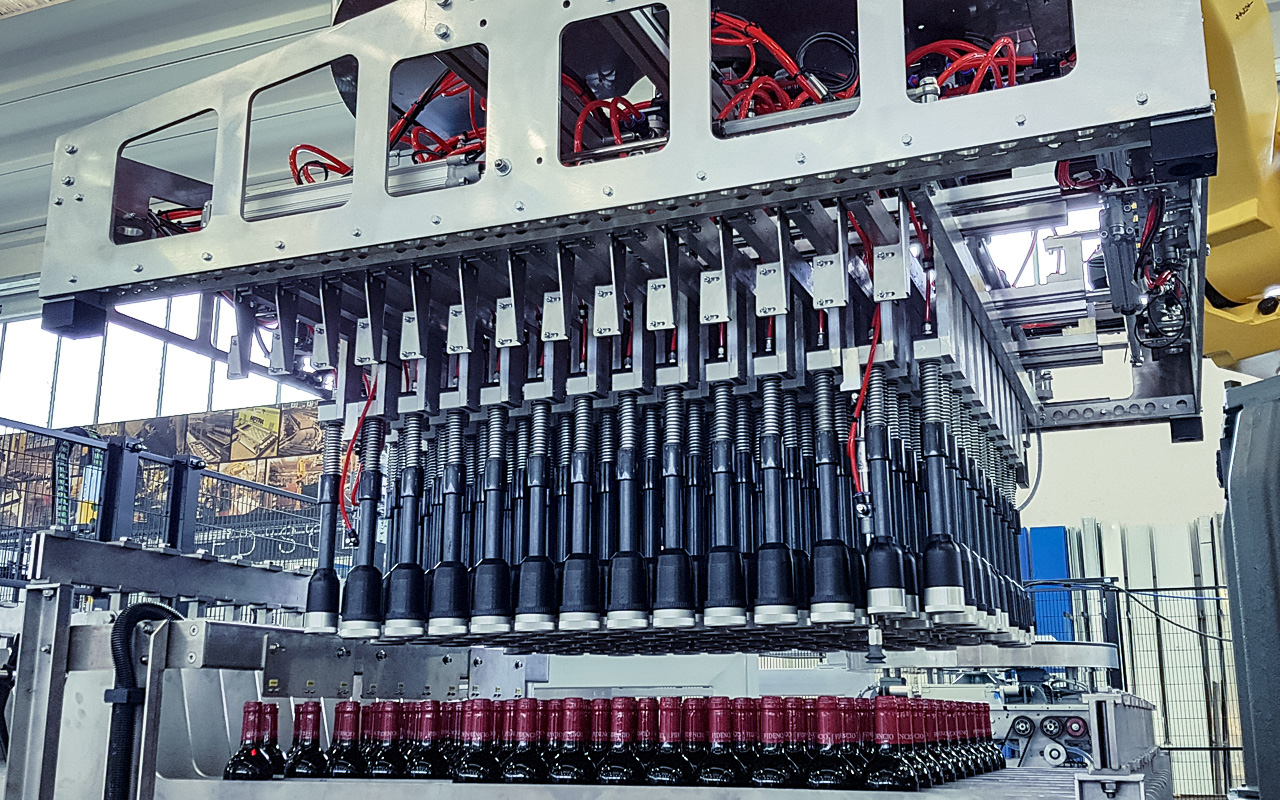

TULIPES PICK-UP

Pick-up head with pneumatically controlled tulipes, sized according to the type of bottle to be handled.

BLADDERS PICK-UP

Inflatable bladders pick-up head sized according to the type of bottle to be handled.

GRIPPER PICK-UP

Mechanical gripper pick-up head for unpacked containers.

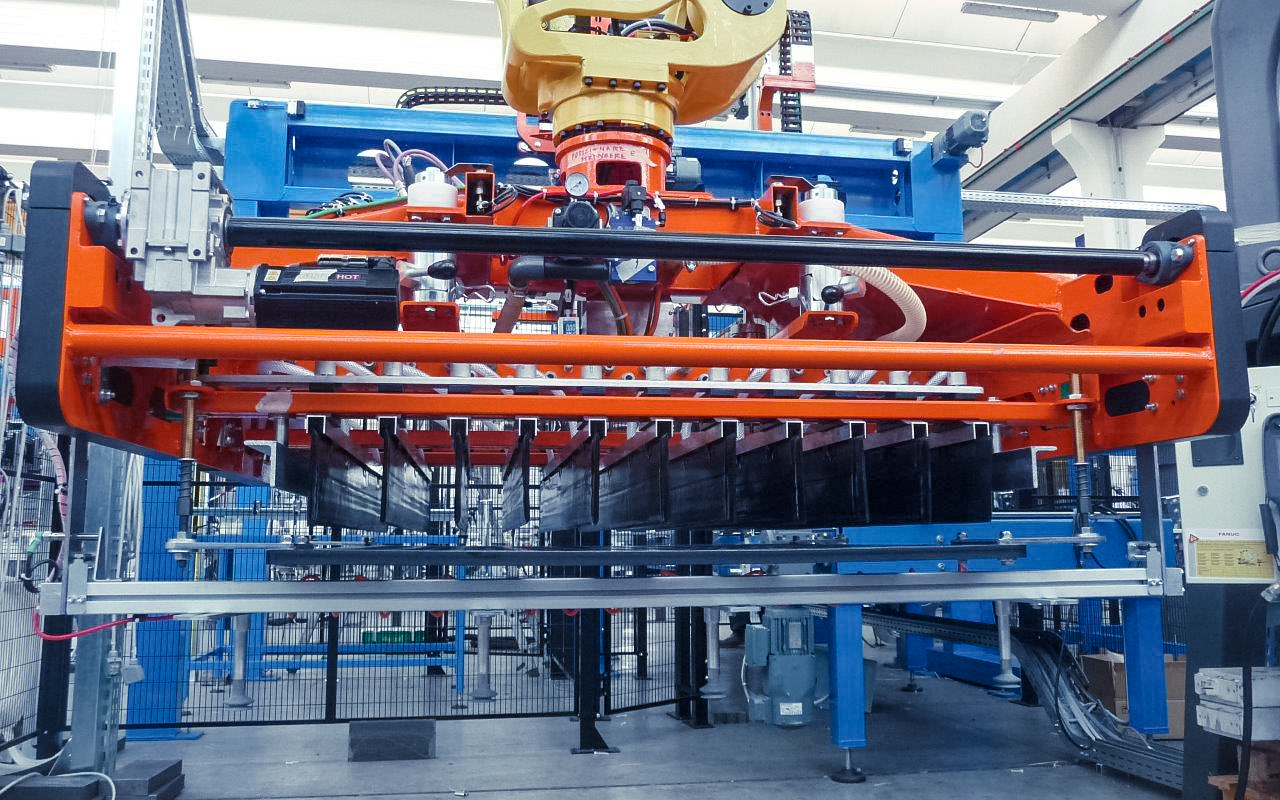

RUBBERIZED LATERAL GUIDES

Head complete with rubberized lateral guides and electro-pneumatic controlled opening and closing. Ideal for palletizing plastic crates and kegs.

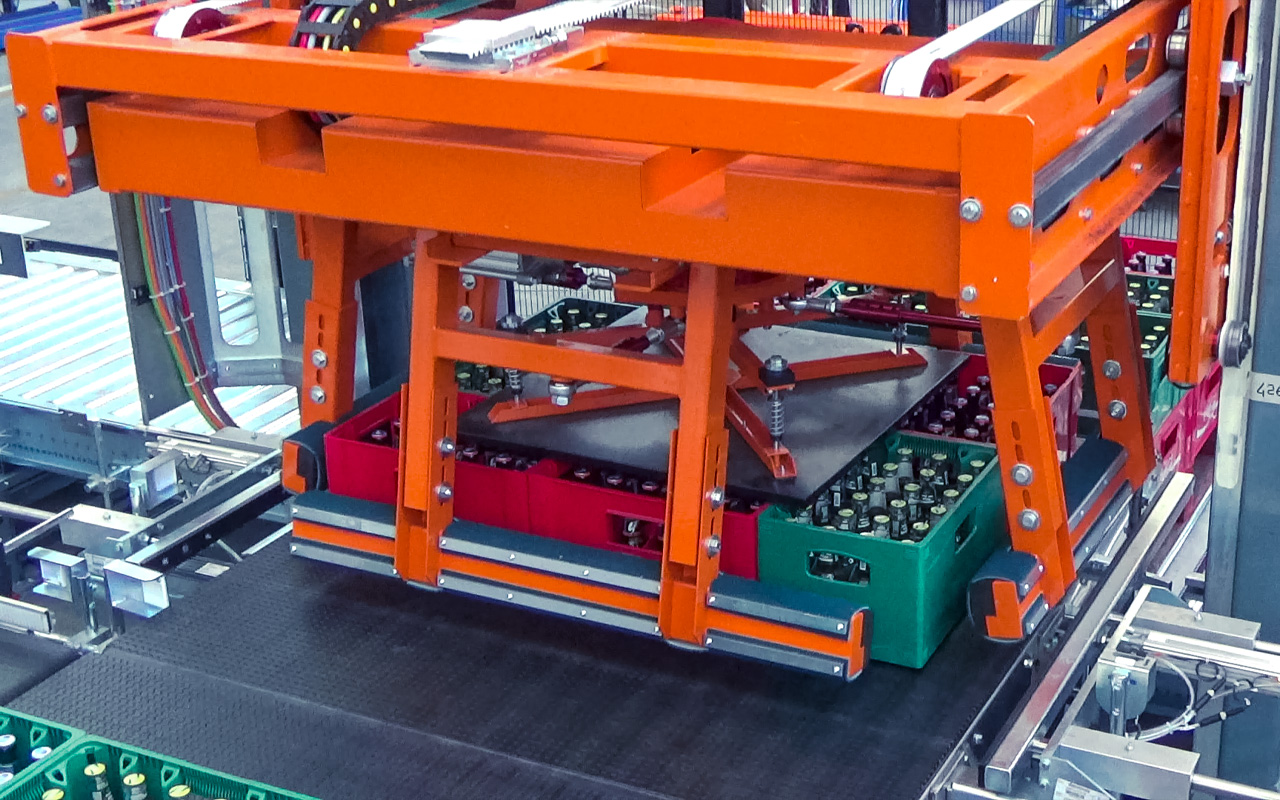

HOOKED

Head complete with side pick-up hooks and electro-pneumatic controlled opening and closing. Ideal for palletizing plastic crates.

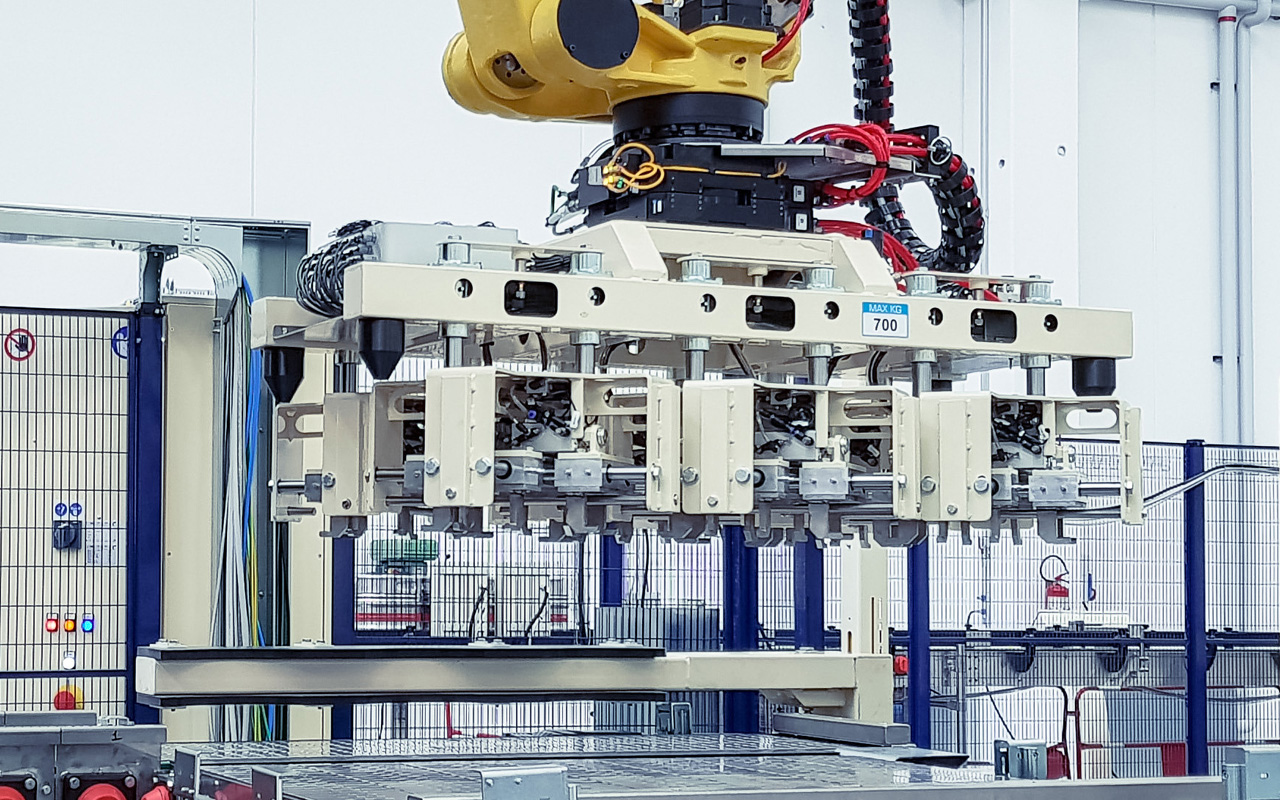

SINGLE AND MULTIPLE SIDE PICK-UP

(for robotic solutions)

Pick-up head with side grippers and electro-pneumatic controlled opening and closing movements.

FORK/CHAIR FOR SINGLE AND MULTIPLE PICK-UP

(for robotic solutions)

Pick-up head for single or multiple rows complete with fork and upper load stabilizer.

FORK FOR ENTIRE LAYER

(for robotic solutions)

Layer pick-up head with central opening motorized fork complete with layer side stabilizers.

VACUUM FOR PET

Vacuum pick-up head designed to process empty bottles regardless of their format (special bottles). Automatically adjustable.

MPH (MULTI-PURPOSE HEAD)

Ideal universal head for palletizing particularly unstable formats that require sweep-off operation.

AUXILIARY SYSTEMS

T-FORMER

GLUE OR INTERLOCKING TRAY FORMATION SYSTEM

Up to 6 cycles/minute

STRENGTHS

- Tray interlocking system facing outwards so as to not obstruct the internal area and compromise product insertion (patent pending).

- User-friendly.

- Facilitated automatic or manual adjustment.

- Maximum layout configuration versatility.

- High accessibility.

T-FORMER

GLUE TRAY FORMATION SYSTEM

STRENGTHS

- User-friendly.

- Maximum layout configuration versatility.

- High accessibility.

STACKER

Our stacker range meets all handling requirements thanks to the various operating modes.

SWEEP-OFF MODE

- Traditional sweeping operation.

- Assisted sweeping operation.

PICK-AND-PLACE MODE

- Inflating tubes/pincers and row approaching: mainly used for oval/conical bottles, for which accumulation is to be avoided.

- Inflating/mechanical fingers/pick-up systems and row approaching: mainly used for special shaped jars, for which accumulation is to be avoided.

- Fingers/cups/tulipes and bottle spacing: mainly used in case of palletization inside thermoformed layer separators or partitions.

REDFOX

LAYER PREPARATION SYSTEM

Up to 150 handling operations/minute

STRENGTHS

- Total application flexibility and high operational autonomy thanks to the three independent handling units with the variable opening gripper and the EMS Layer Optimizer software.

- Multiple simultaneous handling – up to 6 product units.

- Product integrity is guaranteed by full control of the applied pressure.

- Instant and automatic format change via HMI.

- Optimized distribution of the workload on the manipulators for high efficiency.

- Reduced maintenance thanks to the implementation of brushless motors.

LAYER PREPARATION SYSTEM WITH ROBOTIZED MANIPULATORS

STRENGTHS

- MTBF: 60,000 hours.

- High reliability.

- Multiple simultaneous handling – up to 8 product units.

- Product integrity is guaranteed by full control of the applied pressure.

- Instant and automatic format change via HMI.

- Fanuc drive for gripper opening and closing.

R-SHUTTLE

SHUTTLE ON RAIL

STRENGTHS

- Up to 4 pallet stations.

- Capacity up to 1500 kg for each pallet station.

- Load stability guaranteed by top pressure unit.

- High safety guaranteed by PLS, bumper and telescopic approach system for pallets loading/unloading.

- High speed and low noise thanks to vulkolan wheels.