EASYROCK

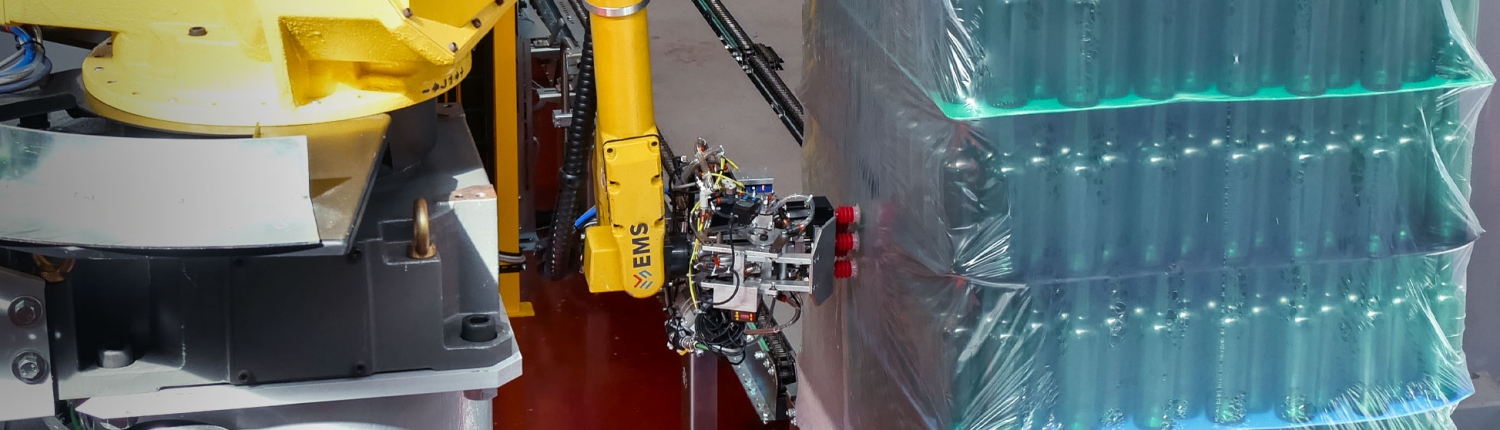

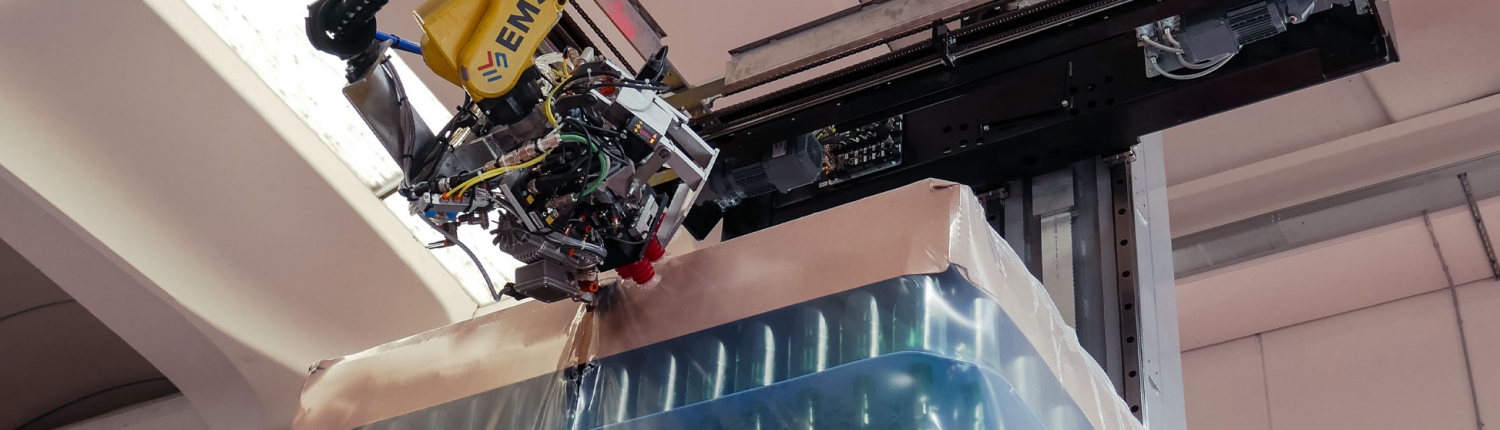

The EASYROCK robotic system ensures reliability, efficiency and flexibility in the removal of shrink film and straps from loading units of hollow glass on pallets intended for subsequent depalletizing.

The self-learning/size detecting system of the load unit on the pallet allows EASYROCK to determine its workability in advance and to correctly manage all operations.

The centering device positioned at the beginning of the line ensures the pallet is centered on the conveyor, preventing problems during the subsequent processing stages.

STRENGTHS

- Able to process load units on pallets of different sizes, thanks to automatic detection of the LU configuration.

- Automatic detection of the workability of the loading unit on pallets (product inclination and shrink film integrity assessment).

- Option to de-film from different types of pallet loading units with the same system to feed multiple depalletizing lines.

- Predefined cutting trajectories for dividing the packaging into two or more parts.

- Cutting system designed to ensure the integrity of the product and of the interlayers.

- Capacity based on the LU type and the layout configuration.

- Reduced maintenance costs thanks to the use of robotics.

- Smaller footprint and high accessibility for reset and cleaning operations.

FOCUS ON

Flexibility

In case of damaged film in the lower part of the loading unit, EASYROCK also ofers the option to only carry out the film cutting cycle in the upper part. This way, the load unit is prevented from being rejected and the operator can safely complete the film cutting and removal.

Sustainability

The EASYROCK motorized rotating blade cutting system drastically reduces the use of heating elements or hot air blows to cut the film, significantly decreasing energy consumption.

Safety

The use of EASYROCK at the infeed of the depalletizing lines increases the overall safety of the working environment as it eliminates the risks associated with manual film removal (use of cutting tools and ladders, passage on handling conveyors).