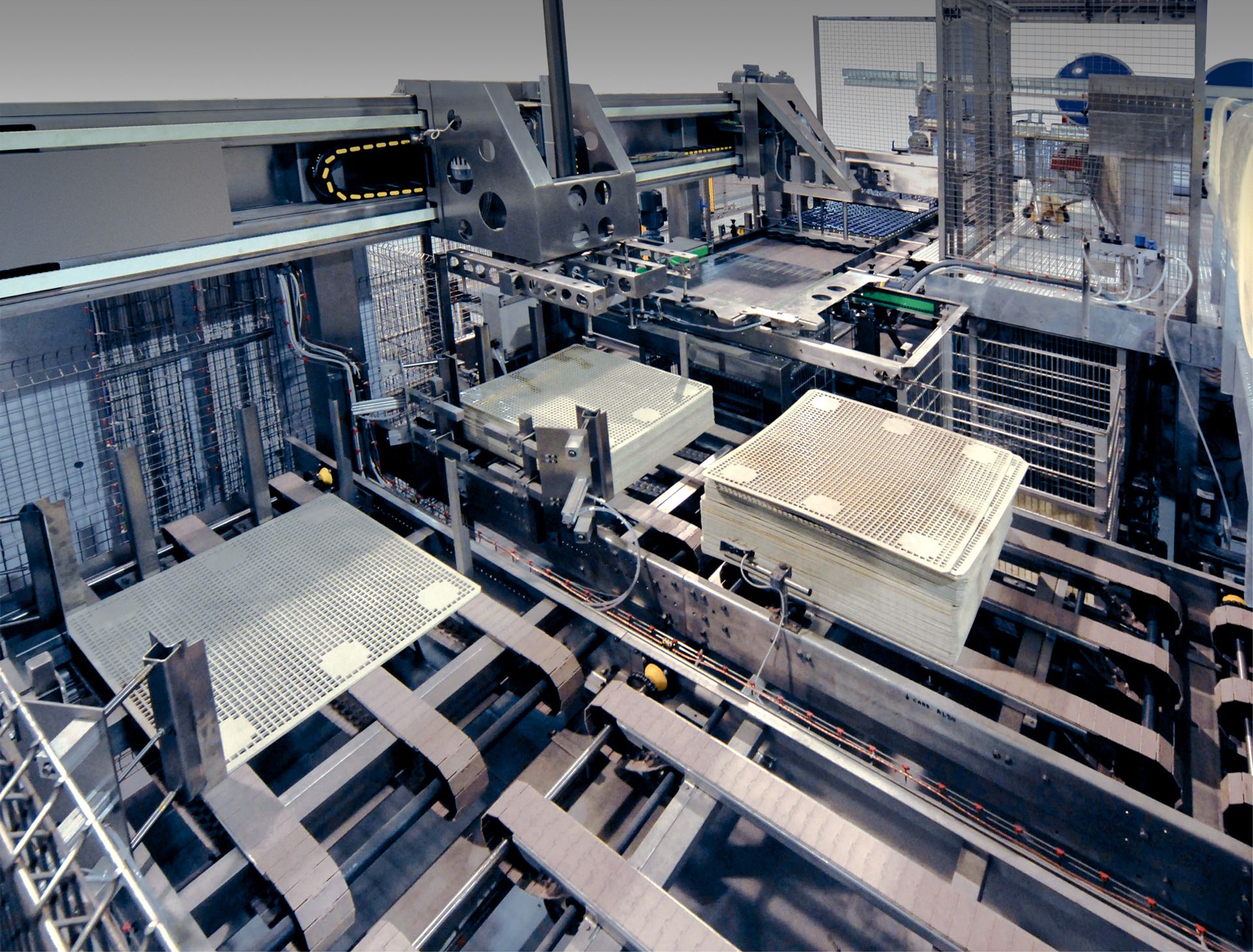

Our basket loaders/unloaders ensure basket loading/unloading reliability and efficiency with products that must undergo an autoclave sterilization cycle. They are designed around a modular concept involving two types of basket loaders/unloaders: one using a Cartesian system and one with an anthropomorphic robot. The different types of heads – magnetic, linear transfer and vacuum – are interchangeable and enable management of a wide range of products with total reliability.

Our basket loaders/unloaders can be integrated with auxiliary systems, such as:

- Automatic interlayers stack handling.

- Automatic spacers stack feeding.

- Tilting unit for water draining (up to 5 baskets).

- Shuttle with motorized hook for partial loading/unloading of autoclaves (up to 6 baskets).

- Automatic product picking system for random sample checks.

SOLUTION

EASY-LOADER

CARTESIAN SYSTEM

Up to 3,5 layers/minute

STRENGTHS

- Structure entirely made of stainless steel.

- Container integrity is ensured as a result of the option to adjust the system’s speed.

- Compact, flexible layout.

- Vertical movement and horizontal shift are achieved through toothed belts to reduce system maintenance and noise.

- User-friendly operator interface.

- It enables the creation of new basket loading/unloading programs directly from the HMI.

- Centralized lubrication.

EASY-UNLOADER

CARTESIAN SYSTEM

Up to 3,5 layers/minute

STRENGTHS

- Structure entirely made of stainless steel.

- Container integrity is ensured as a result of the option to adjust the system’s speed.

- Compact, flexible layout.

- Vertical movement and horizontal shift are achieved through toothed belts to reduce system maintenance and noise.

- User-friendly operator interface.

- It enables the creation of new basket loading/unloading programs directly from the HMI.

- Centralized lubrication.

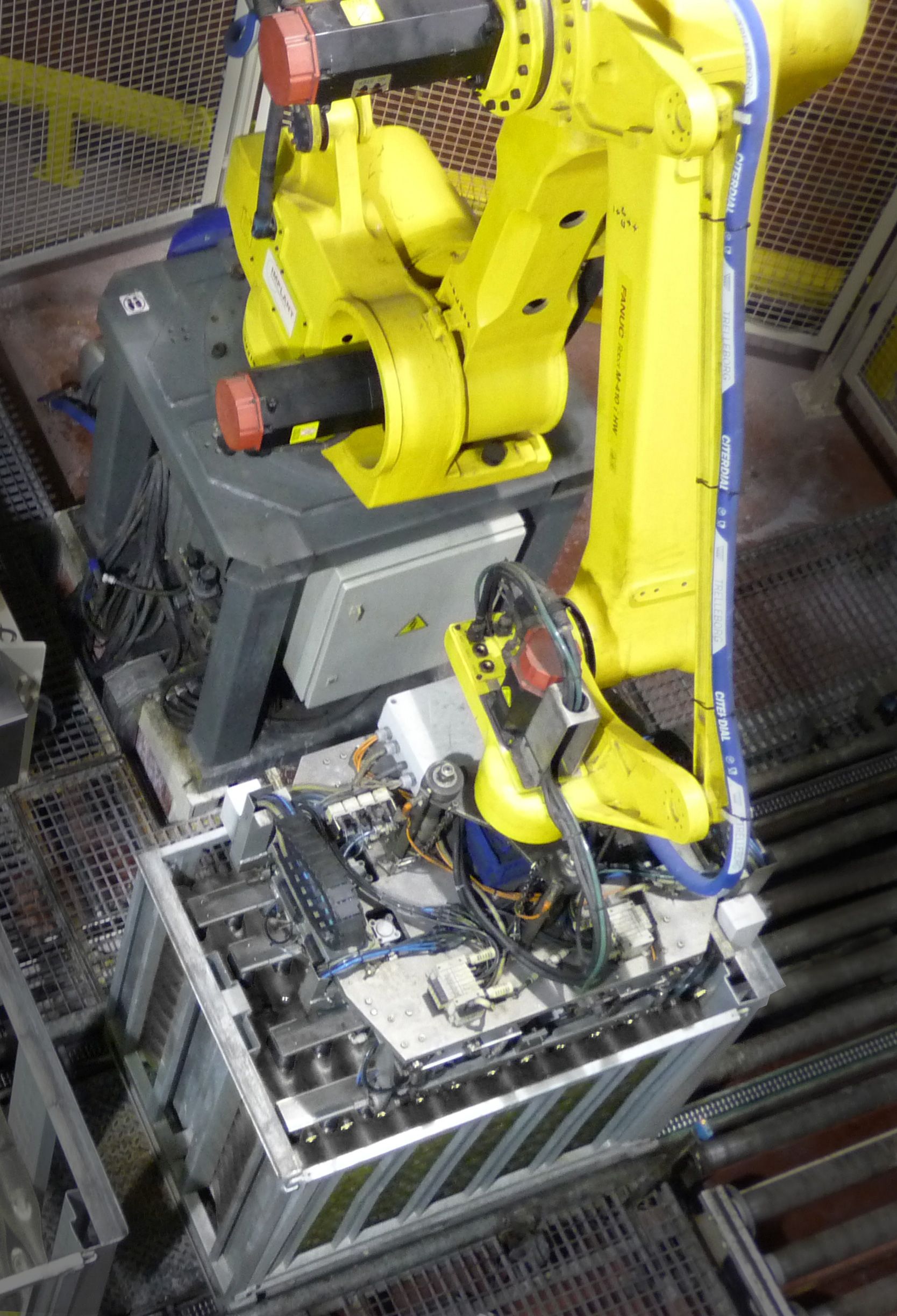

ROBO-LOADER

ANTHROPOMORPHIC ROBOT

Up to 5.5 layers/minute

STRENGTHS

- Container integrity is ensured as a result of the option to adjust the system’s speed.

- Compact, flexible layout.

- User-friendly operator interface.

- It enables the creation of new basket loading/unloading programs directly from the HMI.

- Reduced maintenance.

- High production capacity.

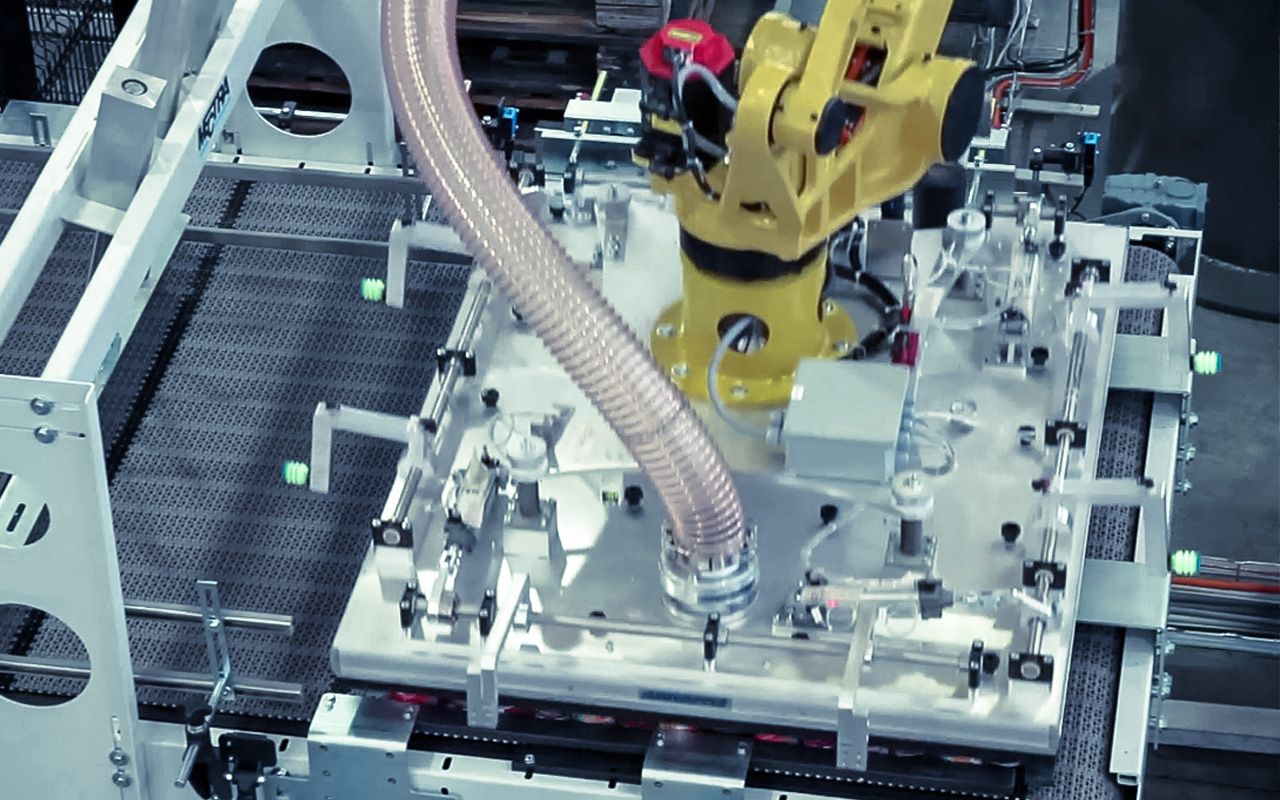

HEADS

MAGNETIC

Ideal for glass jars with tinplate twist-off cap as well as tinplate cans. It can also handle interlayers and spacers.

LINEAR TRANSFER

Ideal for aluminum and tinplate cans as well as glass jars.

VACUUM

“Vacuum” type of transfer head ideal for aluminum cans, jars and doypack.