Our depalletizing systems are designed according to a modular concept that involves two types of depalletizers to implement with interchangeable pick-up heads: one depalletizer with a single column structure equipped with a Cartesian system and one with an anthropomorphic robot.

All our depalletizers ensure:

- Maximum application and configuration flexibility.

- High efficiency.

- Optimum accessibility.

SOLUTIONS

R-DEPAL

ROTATING SINGLE-COLUMN

Up to 4 layers/minute

STRENGTHS

- Maximum layout configuration flexibility.

- Format change directly from HMI.

- Simple installation.

- Reduced maintenance thanks to the use of toothed belts.

- Anti-fall system for all the hanged loads.

- High accessibility.

T-DEPAL

TRANSLATING SINGLE-COLUMN

Up to 4 layers/minute

STRENGTHS

- Maximum layout configuration flexibility.

- Format change directly from HMI.

- Simple installation.

- Reduced maintenance thanks to the use of toothed belts.

- Anti-fall system for all the hanged loads.

- High accessibility.

ROBO-DEPAL

WITH ANTHROPOMORPHIC ROBOT

Up to 5 layers/minute

STRENGTHS

- MTBF: 60,000 hours.

- Possibility to work simultaneously on several stations.

- Possibility to equip with pick-up heads for entire layer, single row or multi-row according to production requirements.

- Format change directly from HMI.

- Maximum layout configuration flexibility.

- High accessibility.

PICK-UP HEADS

The pick-up heads can be applied to the single column depalletizer as well as the robotic depalletizer and enable management of a wide range of products with maximum reliability, ensuring pick and place operation precision and integrity of the product handled. Depending on requirements, they can also be equipped with equipment for handling interlayers, pallets and frames.

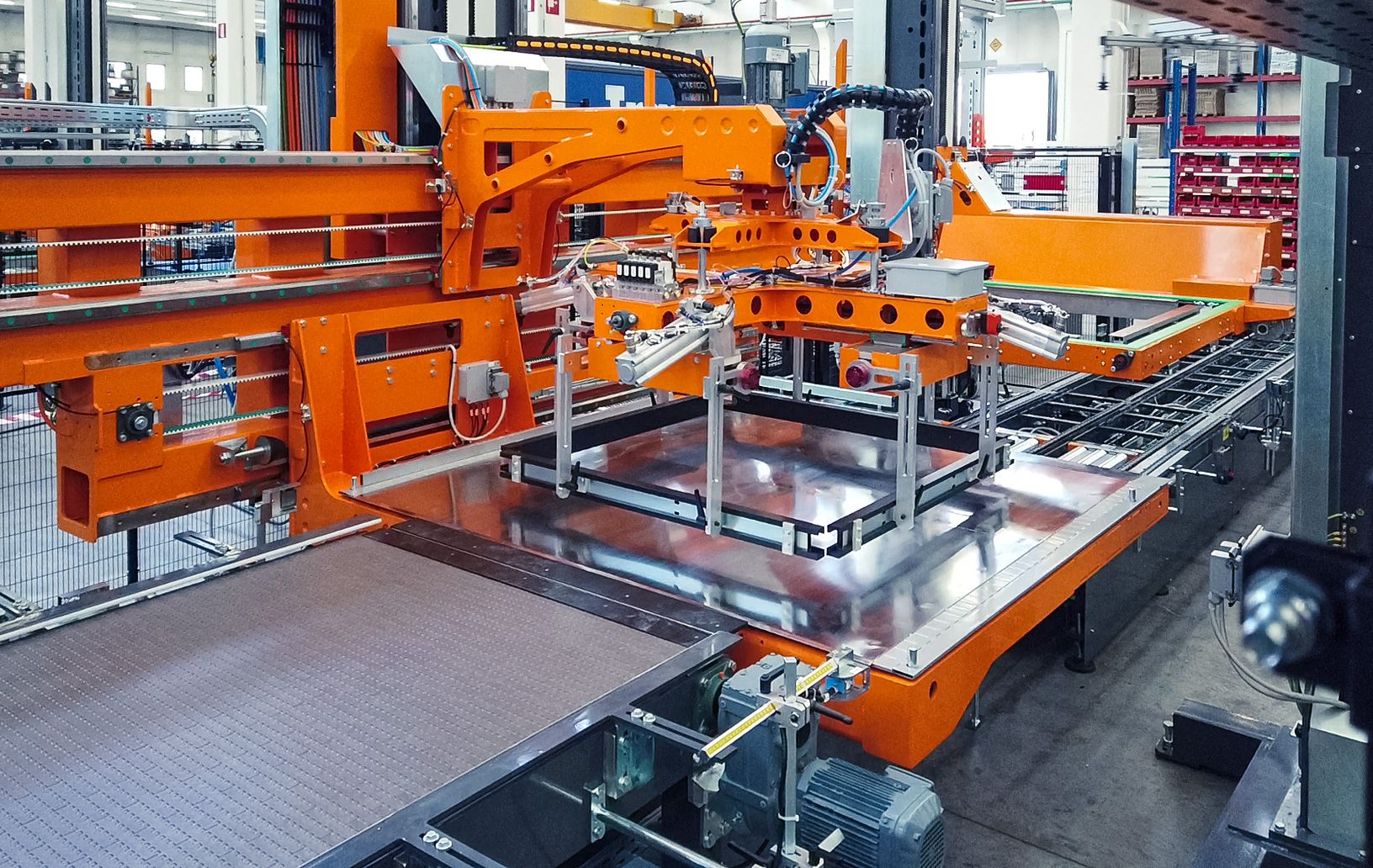

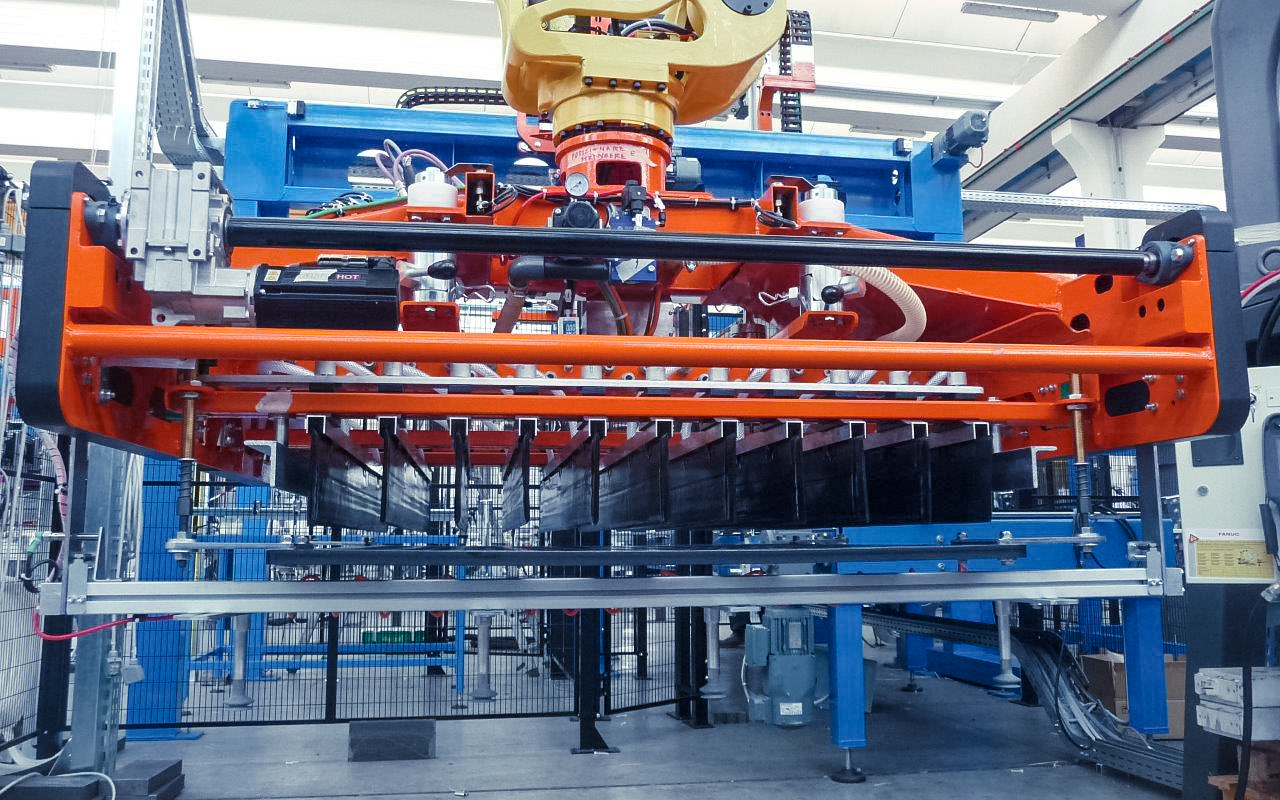

SWEEP-OFF

Universal palletizing and depalletizing head complete with motorized layer compacting guides.

MAGNETIC

Magnetic head with automatic quick release grid.

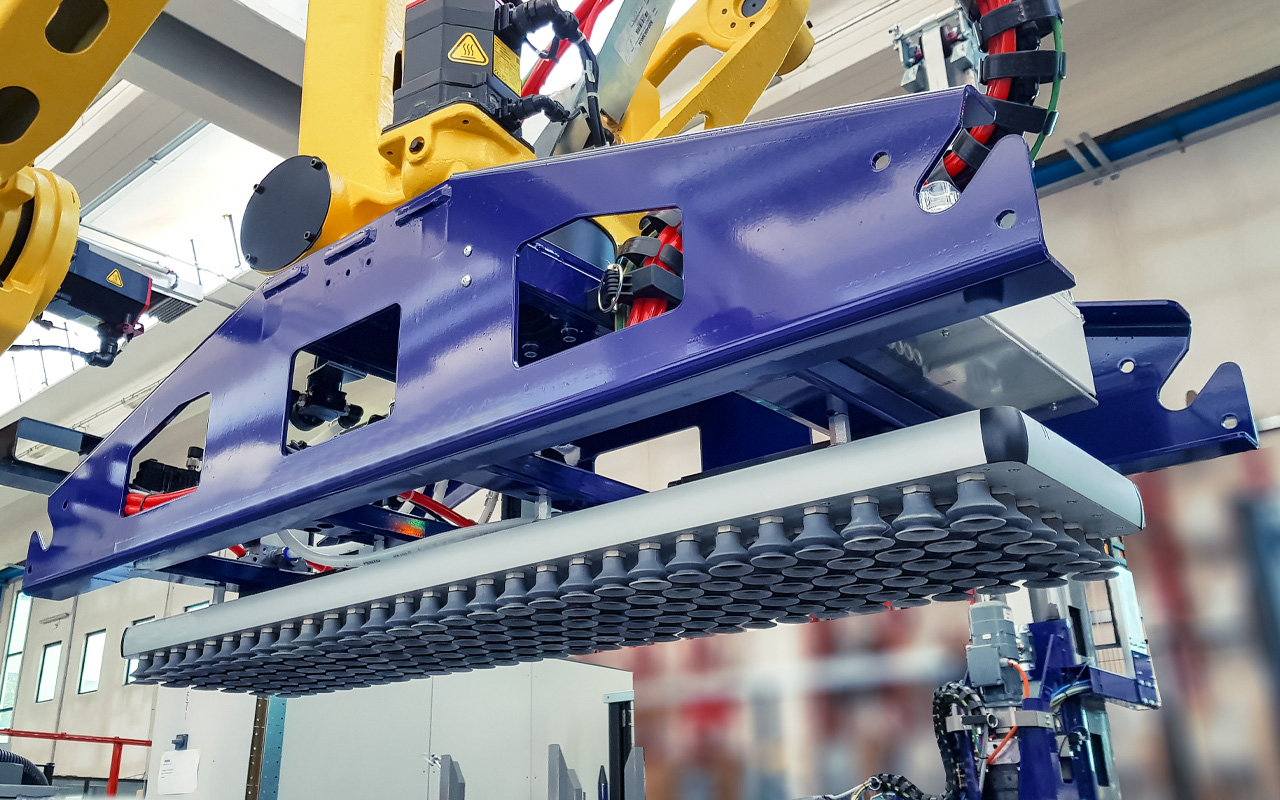

VACUUM

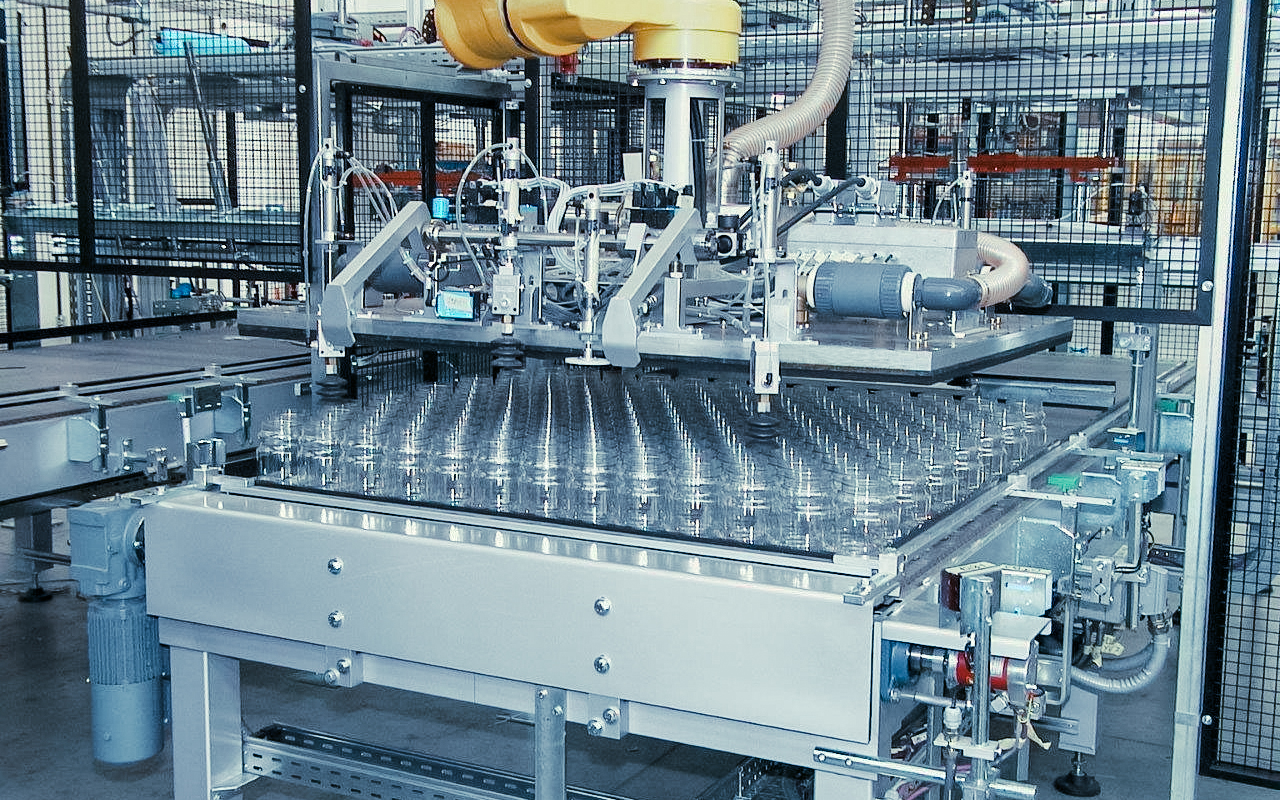

Vacuum pick-up head ideal for handling glass jars, loose, bundled and clustered cans and boxes.

UNIVERSAL SIDE PICK-UP AND VACUUM

Universal vacuum pick-up head complete with lateral electro-pneumatic controlled compaction guides.

TULIPES PICK-UP

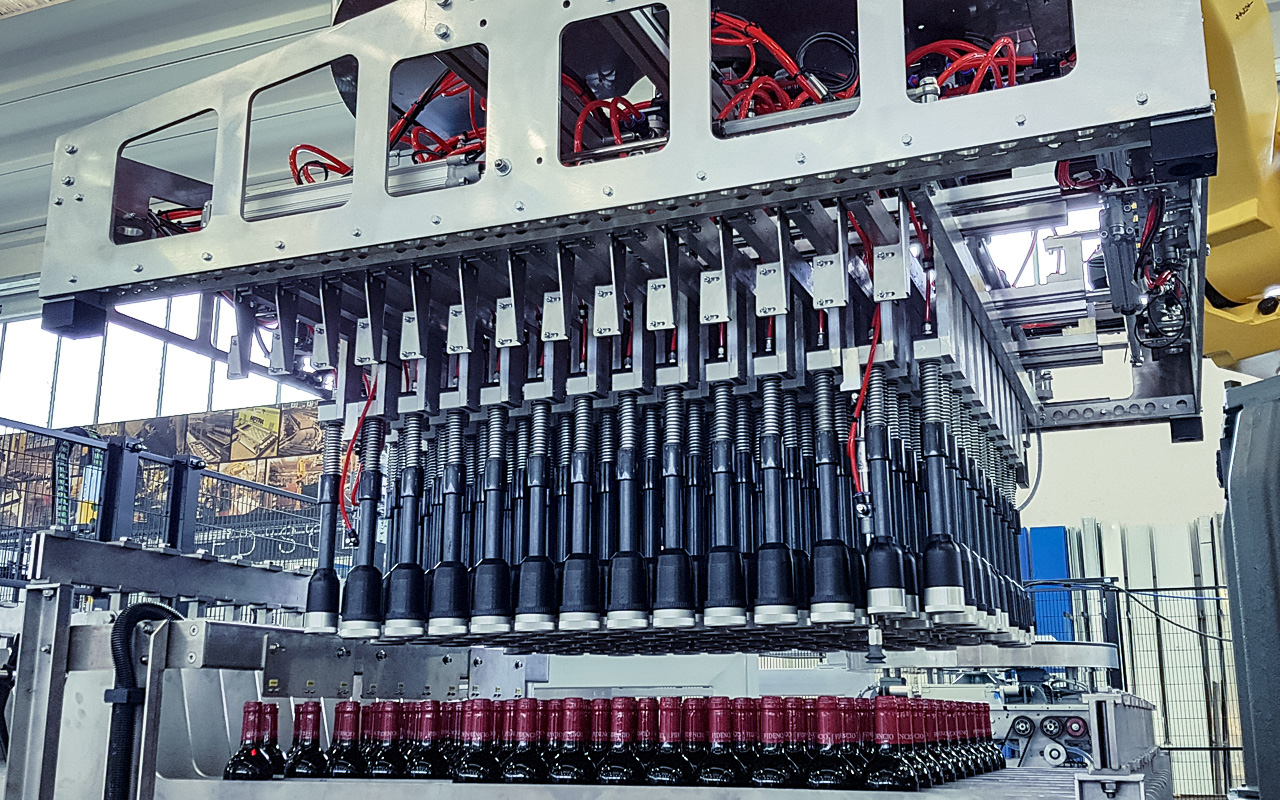

Pick-up head with pneumatically controlled tulipes, sized according to the type of bottle to be handled. Suitable also for pallet displays.

BLADDERS PICK-UP

Inflatable bladders pick-up head sized according to the type of bottle to be handled.

GRIPPER PICK-UP

Mechanical gripper pick-up head for unpacked containers.

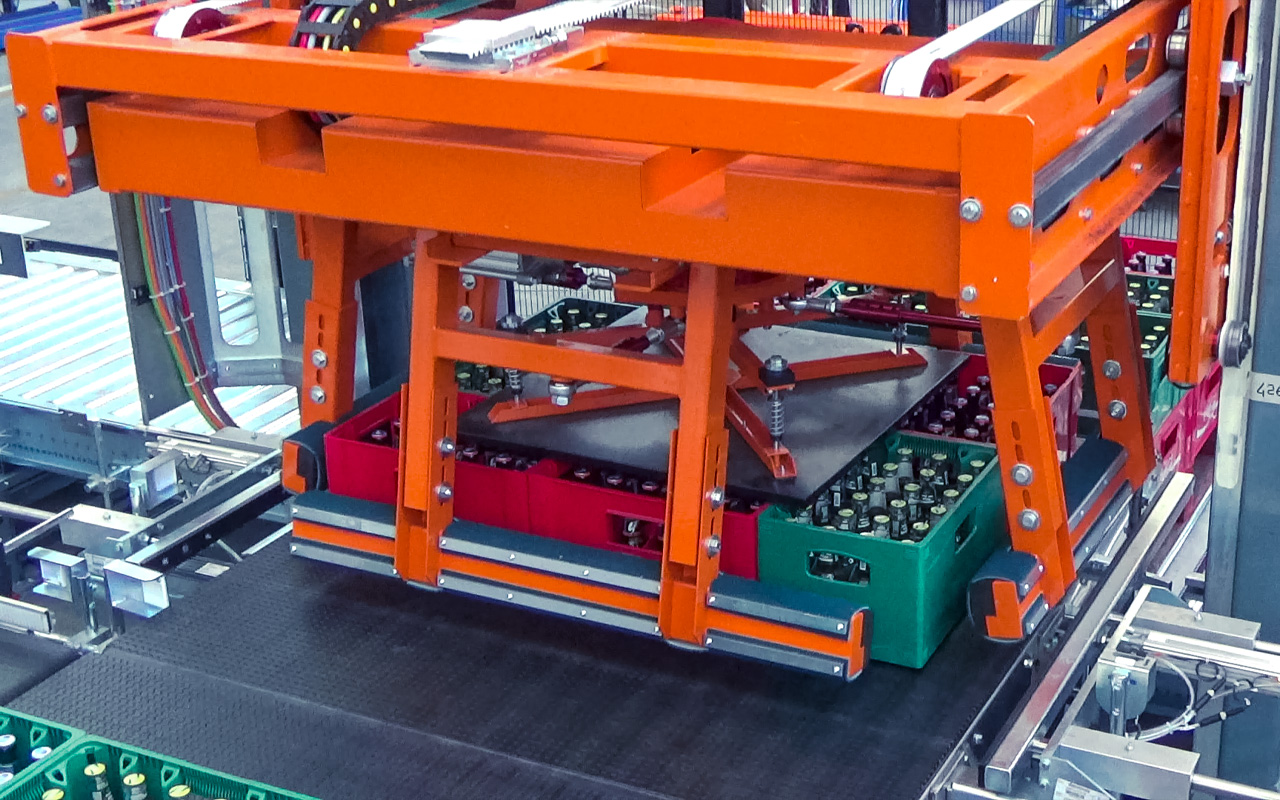

RUBBERIZED LATERAL GUIDES

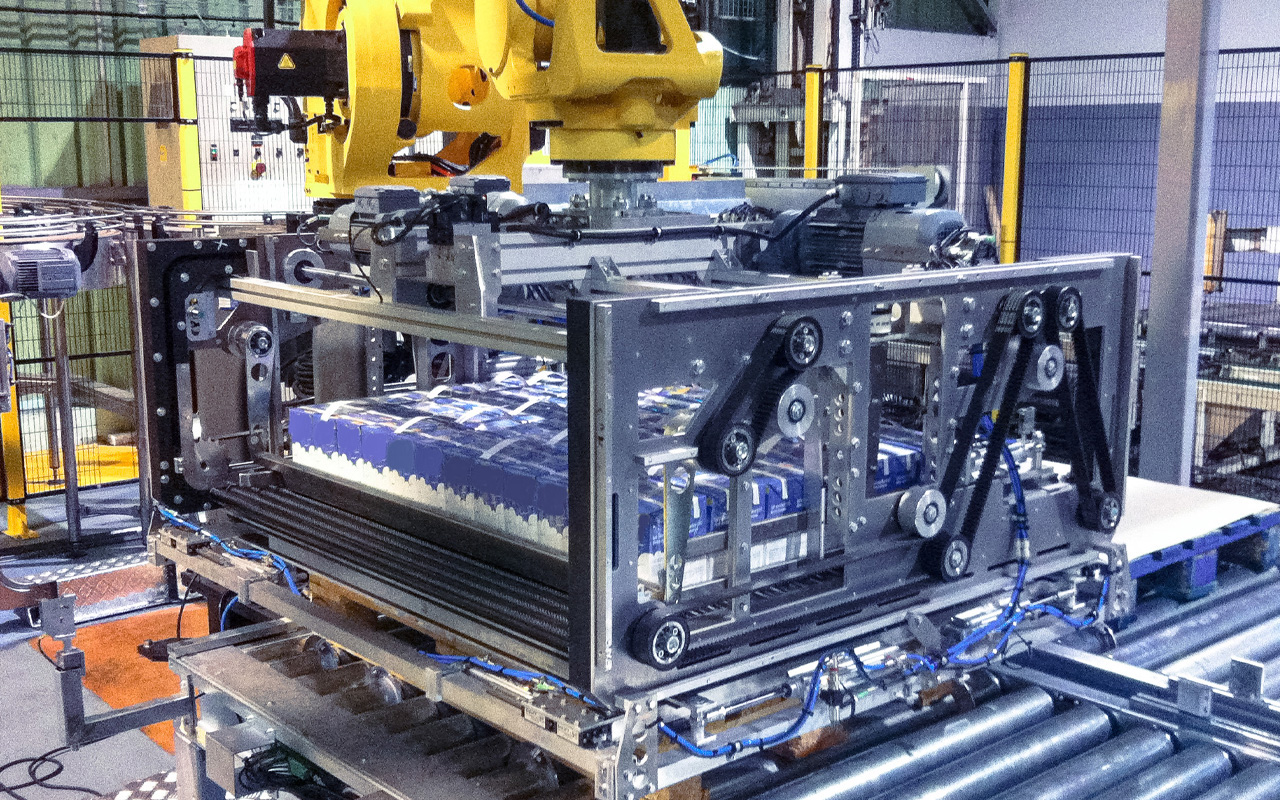

Head complete with rubberized lateral guides and electro-pneumatic controlled opening and closing. Ideal for palletizing plastic crates and kegs.

HOOKED

Head complete with side pick-up hooks and electro-pneumatic controlled opening and closing. Ideal for palletizing plastic crates.

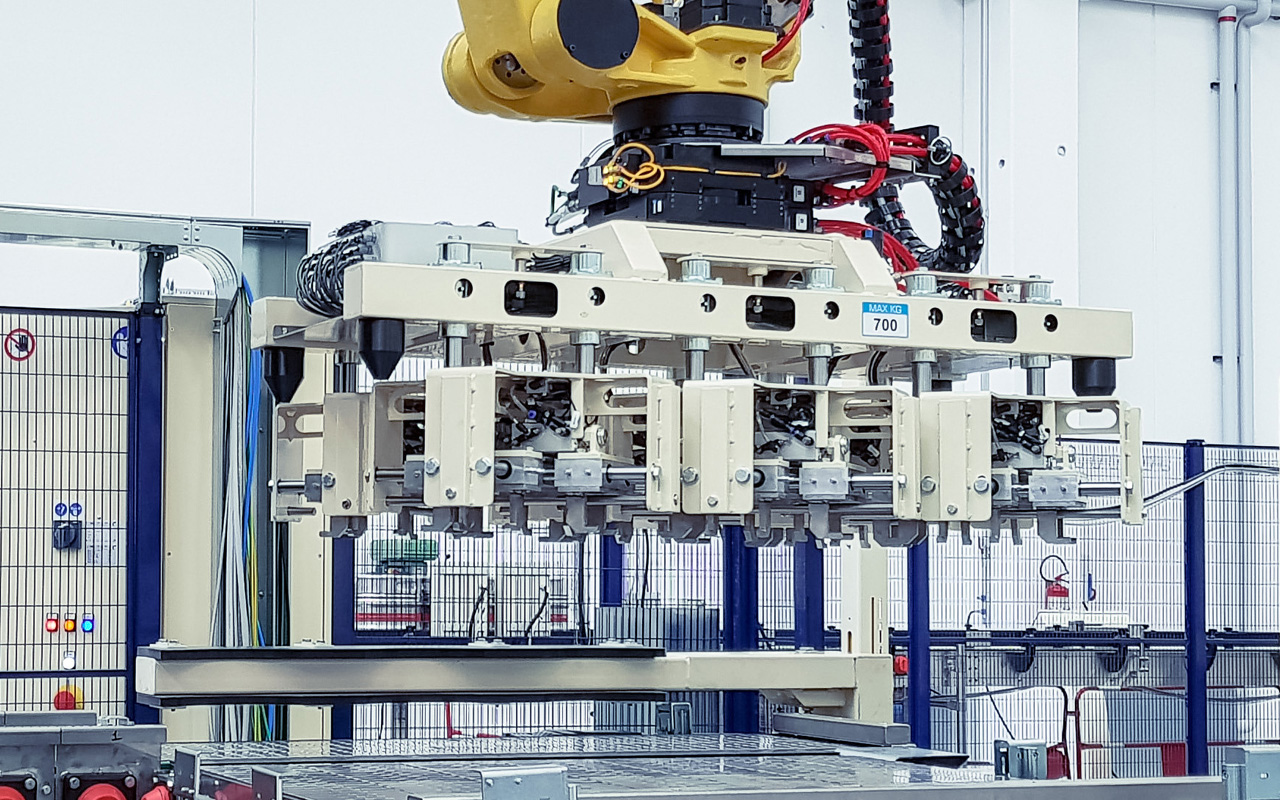

SINGLE AND MULTIPLE SIDE PICK-UP

(for robotic solutions)

Pick-up head with side grippers and electro-pneumatic controlled opening and closing movements.

VACUUM FOR SINGLE AND MULTIPLE PICKING-UP

(for robotic solutions)

Vacuum head, suitable also for repacking processes.

AUXILIARY SYSTEMS

CARTON CAP FLAP OPENING SYSTEM

STRENGTHS

- Four blades controlled by a cylinder and protected by Plexiglas, situated on a painted steel structure.

- Magazine filling level control photocell.

- Warning light alarm for full magazine signal.

- Pneumatically controlled finger unit situated on the two sides of the magazine to keep 5/6 open trays in position before being transferred to the pallet.

- Hydraulic lifter for acceleration and control of open tray positioning.

- Magazine with pallet on the ground.

ROBOT FOR IDENTIFICATION AND PICKING OF DIVIDERS BETWEEN THE BOTTLES

STRENGTHS

- Fanuc Robot.

- Head complete with 2 grippers each with 4 shaped fingers based on the bottles to be handled.

- 2 cameras for positioning control of the grippers during the picking stage.