Ideal for storing products of various sizes on trays, our automated warehouses maximize vertical storage spaces and speed up pick-ups, according to the «goods to man» operating concept.

STRENGTHS

- Quick and easy operations thanks to a single placement and pick-up point.

- Material pick-up and placement possible from any bay.

- High flexibility design: option of providing one or more bays, on the same side or on different sides, based on the needs.

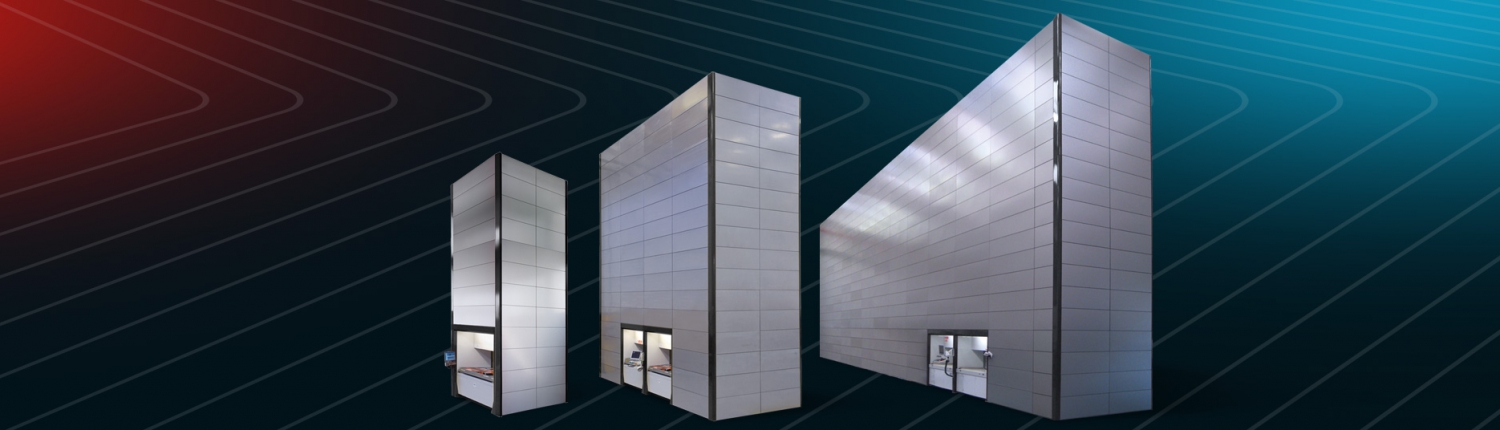

UNO

Automated warehouse with single module, 2 axes, one bay

STRENGTHS

- Tray pick-up/placement trolley on both sides.

- Can be placed both inside and outside the plant.

- Standard maximum height: 14 m.

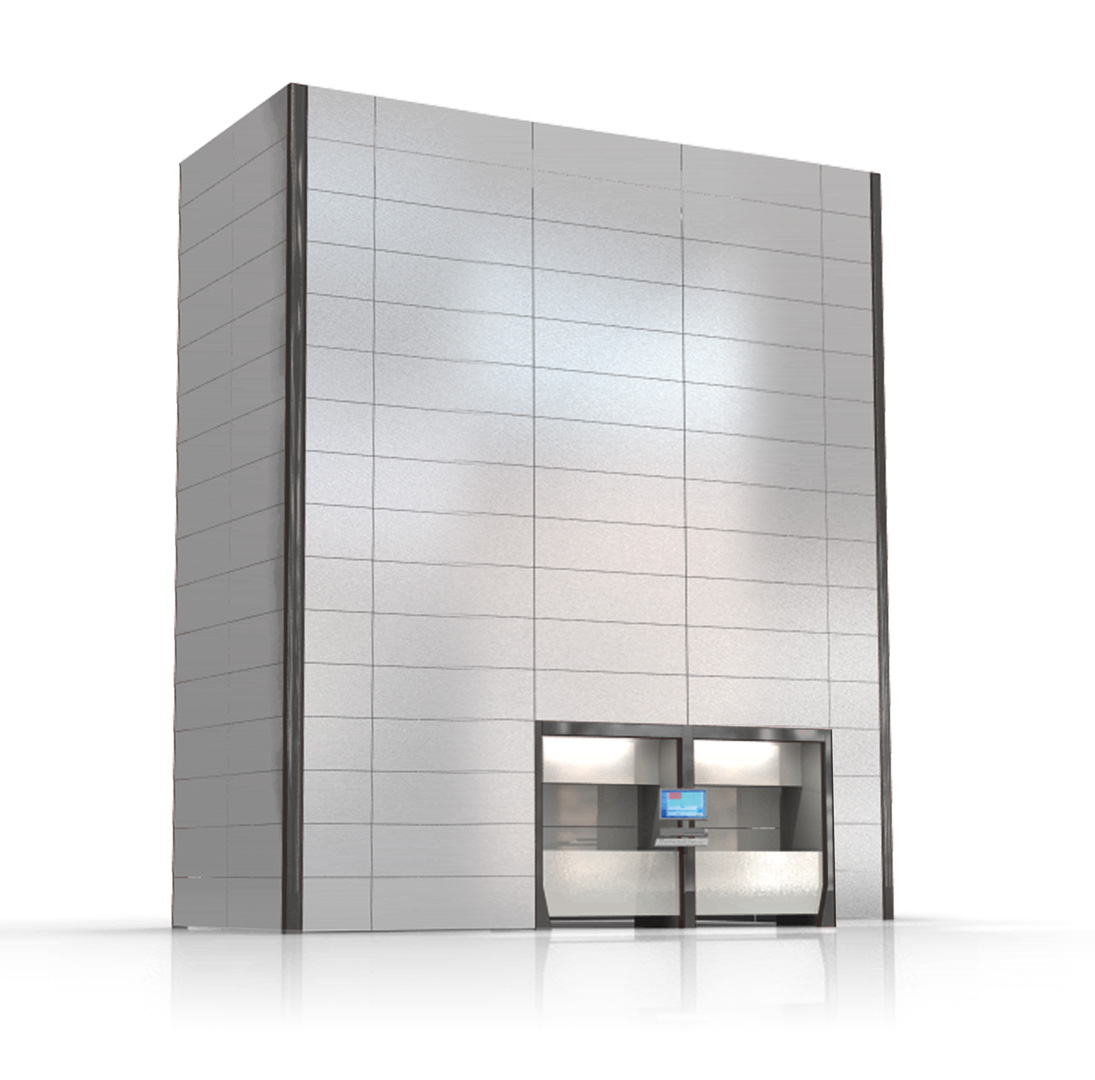

SPAZIO

Automated warehouse with 2 to 10 modules, 3 axes, one or more bays

STRENGTHS

- Tray pick-up/placement trolley on both sides.

- Can be placed both inside and outside the plant.

- Option of combining multiple systems with interchange bays for increased storage capacity.

- Standard maximum height: 14 m.

- Maximum achievable length: 10 m (beam limit).

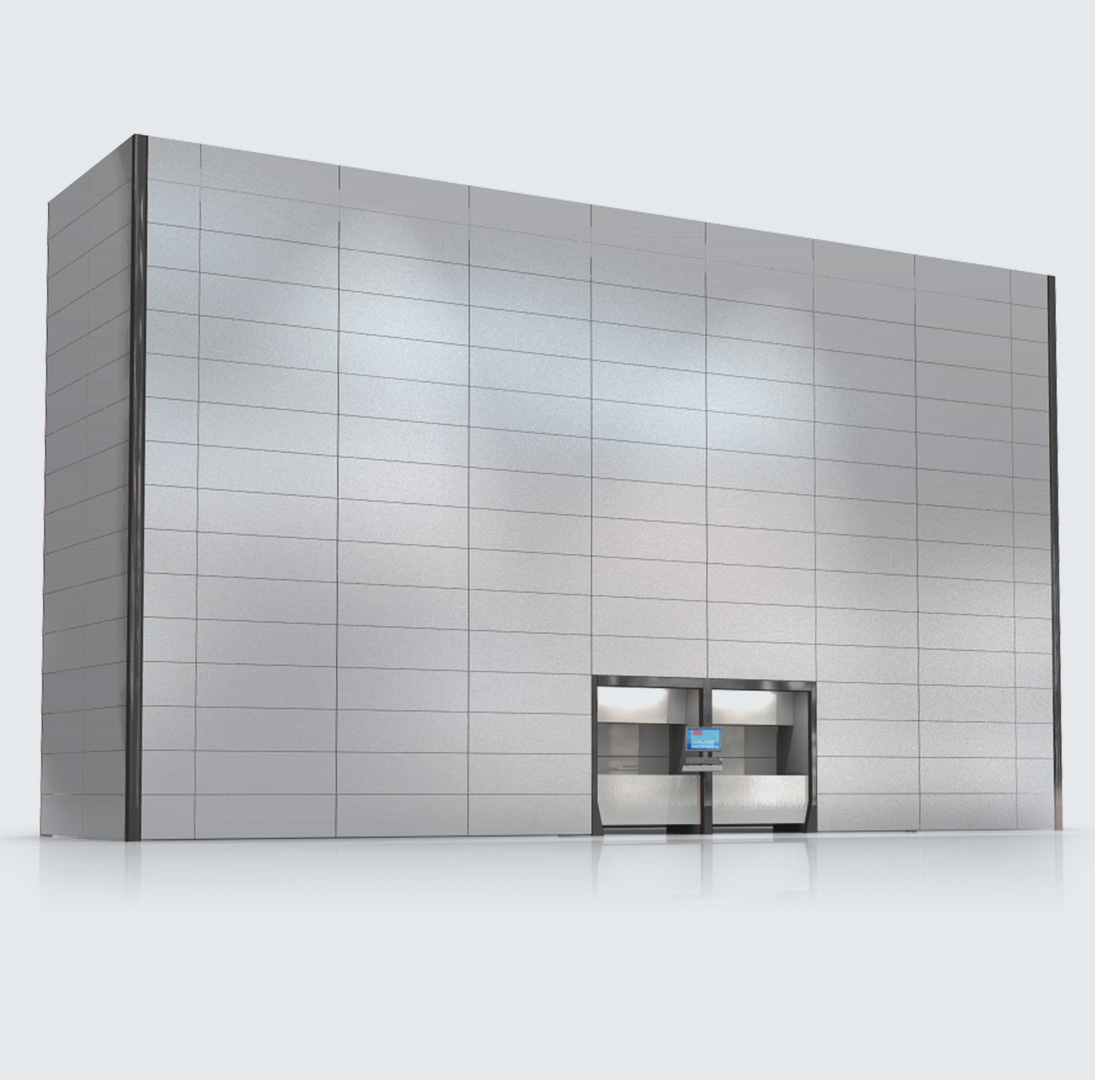

UNICO

Automated warehouse with multi-module, 3 axes, one or more bays

STRENGTHS

- Option of increasing the number of modules, at any time, while maintaining the same handling system.

- Double column stacker creane that moves inside the warehouse through all modules (horizontal and vertical movement).

- Tray placement on the front and rear shelves.

- Tray pick-up/placement trolley both front and rear of the system.

- Can be placed both inside and outside the plant.

- Option of combining multiple systems with interchange bays for increased storage capacity.

- Standard maximum height: 14 m.